1

The structure of the touch screen (touchscreen) and the problems associated with its replacement

Touch screen - a device for input and output of information, which is a screen that reacts to touching it.

Resistive touch screen

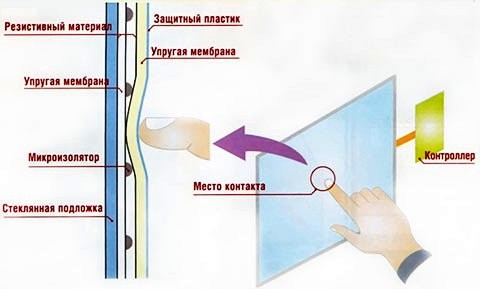

The resistive touch screen consists of a glass panel and a flexible plastic membrane. Both the panel and the membrane have a resistive coating. The space between the glass and the membrane is filled with micro-insulators, which are evenly distributed over the active area of the screen and reliably isolate conductive surfaces. When the screen is pressed, the panel and membrane are closed, and the controller, using an analog-to-digital converter, registers the change in resistance and converts it into touch coordinates (X and Y).

In general terms, the reading algorithm is as follows:

1. A voltage of + 5V is applied to the upper electrode, the lower one is grounded. The left and right are short-circuited and the voltage on them is checked. This voltage corresponds to the Y-coordinate of the screen.

2. Similarly, + 5V and “ground” are supplied to the left and right electrodes, the X-coordinate is read from the top and bottom.

Capacitive touch screens

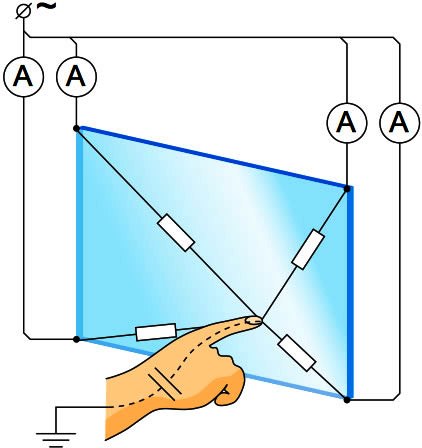

A capacitive (or surface capacitive) screen takes advantage of the fact that an object of high capacity conducts alternating current.

A capacitive touch screen is a glass panel coated with a transparent resistive material (usually an alloy of indium oxide and tin oxide). The electrodes located at the corners of the screen apply a small amount of energy to the conductive layer. AC voltage(the same for all corners). When touching the screen with a finger or other conductive object, current leakage occurs. At the same time, the closer the finger is to the electrode, the lower the resistance of the screen, which means that the current strength is greater. The current in all four corners is recorded by sensors and transmitted to the controller, which calculates the coordinates of the touch point.

Earlier models of capacitive screens used direct current - this simplified the design, but with poor user contact with the ground, it led to failures.

Capacitive touch screens are reliable, with 200 million clicks (about 6 and a half years of clicks every one second), liquid-tight, and non-conductive pollution tolerant. Transparency at 90%. However, the conductive coating is still vulnerable. therefore capacitive screens are widely used in vending machines installed in a protected area. Not responsive to gloved hand.

Multitouch(eng. multi-touch) - a function of touch input systems that simultaneously determines the coordinates of two or more touch points. Multi-touch can be used, for example, to change the image scale: as the distance between touch points increases, the image is enlarged. In addition, multi-touch screens allow several users to work with the device at the same time. They are often used to perform other, simpler functions. touch displays such as single touch or quasi multitouch.

Multi-touch allows you not only to determine the relative position of several touch points at any given time, it determines a pair of coordinates for each touch point, regardless of their position relative to each other and boundaries touch panel. Proper recognition of all touch points enhances the interface capabilities of the touch input system. The range of tasks solved when using the multi-touch function depends on the speed, efficiency and intuitiveness of its application.

The most common multi-touch gestures

Move your fingers - smaller

Spread your fingers - bigger

Multi-finger move - scroll

Rotate with two fingers - Rotate an object/image/video

Resistive Touch Screen Installation Issues![]() Sometimes there is no complete analogue of the desired wheelbarrow at hand, or the pinout of the cable is different, the following problems may occur:

Sometimes there is no complete analogue of the desired wheelbarrow at hand, or the pinout of the cable is different, the following problems may occur:

1. Touch rotated 90.270 degrees

- Swap X-Y ![]()

2. Turned the touch horizontally

- Swap X+ , X-

3. Turn the touch upside down

- Swap Y+ , Y-

These solutions should be carried out if the problem persists after calibrating the touch screen.

Replacing the touch screen did not help.

- Reflash phone

Resistance on TOUCHSCREEN contacts

Y-,Y+=550 Om Without pressing

X-,X+=350 Om Without pressing

Y +, X + = from 0.5 to 1.35 kOm Measurements were made in different corners of the touchscreen when pressed. Without touching the touchscreen, the resistance is infinity.

Y-,X-=from 1.35-0.5 kOm Measurements were made in different corners of the touchscreen when pressed. Without touching the touchscreen, the resistance is equal to infinity.

AT different models touch screens, the resistance may fluctuate. These measurements were made on the touch screen of an I9+++ phone.

When is it time to change the touch screen?

It is time to change the touch screen in the following cases:

- if it does not respond to touch

- you found an "oily spot" on it (multi-color stains)

- unable to calibrate touch screen

- entering the message and selecting the English text input mode, try to put dots over the entire area, if dashes appear instead of dots, then it's time to change

- entering the service-miscellaneous-Touch Screen, try to put dots over the entire area, if green stripes appear instead of crosses - it's time to change

- if you try to click on the icon, the desktops scroll or the icons fall off (vertical shedding of icons in iPhone-like phones)

- if 5 minutes after the calibration you again do not hit the icon you click on

Touch screen- a device for input and output of information, which is a screen that reacts to touching it. In this article, we will study its structure and possible problems associated with its replacement.

The resistive touch screen consists of a glass panel and a flexible plastic membrane. Both the panel and the membrane have a resistive coating. The space between the glass and the membrane is filled with micro-insulators, which are evenly distributed over the active area of the screen and reliably isolate conductive surfaces. When the screen is pressed, the panel and membrane are closed, and the controller, using an analog-to-digital converter, registers the change in resistance and converts it into touch coordinates (X and Y).

In general terms, the reading algorithm is as follows:

1. A voltage of + 5V is applied to the upper electrode, the lower one is grounded. The left and right are short-circuited and the voltage on them is checked. This voltage corresponds to the Y-coordinate of the screen.

2. Similarly, + 5V and “ground” are supplied to the left and right electrodes, the X-coordinate is read from the top and bottom.

A capacitive (or surface capacitive) screen takes advantage of the fact that an object of high capacity conducts alternating current.

A capacitive touch screen is a glass panel coated with a transparent resistive material (usually an alloy of indium oxide and tin oxide). Electrodes located at the corners of the screen apply a small alternating voltage (the same for all corners) to the conductive layer. When touching the screen with a finger or other conductive object, current leakage occurs. At the same time, the closer the finger is to the electrode, the lower the resistance of the screen, which means that the current strength is greater. The current in all four corners is recorded by sensors and transmitted to the controller, which calculates the coordinates of the touch point.

Earlier models of capacitive screens used direct current - this simplified the design, but with poor user contact with the ground, it led to failures.

Capacitive touch screens are reliable, with 200 million clicks (about 6 and a half years of clicks every one second), liquid-tight, and non-conductive pollution tolerant. Transparency at 90%. However, the conductive coating is still vulnerable. Therefore, capacitive screens are widely used in vending machines installed in a protected area. Not responsive to gloved hand.

Multitouch (English multi-touch) - a function of touch input systems that simultaneously determines the coordinates of two or more touch points. Multi-touch can be used, for example, to change the image scale: as the distance between touch points increases, the image is enlarged. In addition, multi-touch screens allow several users to work with the device at the same time. They are often used for other, simpler touch display functions such as single touch or quasi-multi-touch.

Multi-touch allows not only to determine the relative position of several touch points at any given time, it determines a pair of coordinates for each touch point, regardless of their position relative to each other and the boundaries of the touchpad. Proper recognition of all touch points enhances the interface capabilities of the touch input system. The range of tasks solved when using the multi-touch function depends on the speed, efficiency and intuitiveness of its application.

The most common multi-touch gestures

Move your fingers - smaller

Spread fingers - larger

Multi-finger move - scroll

Rotate with two fingers - rotate an object/image/video

Resistive Touch Screen Installation Issues

Sometimes there is no complete analogue of the desired wheelbarrow at hand, or the pinout of the cable is different, the following problems may occur:

1. Touch rotated 90.270 degrees

- Swap X-Y

2. Turned the touch horizontally

- Swap X+ , X-

3. Turn the touch upside down

- Swap Y+ , Y-

These solutions should be carried out if the problem persists after calibrating the touch screen.

Replacing the touch screen did not help.

- Reflash phone

Resistance on TOUCHSCREEN contacts

Y-,Y+=550 Om Without pressing

X-,X+=350 Om Without pressing

Y +, X + = from 0.5 to 1.35 kOm Measurements were made in different corners of the touchscreen when pressed. Without touching the touchscreen, the resistance is infinity.

Y-,X-=from 1.35-0.5 kOm Measurements were made in different corners of the touchscreen when pressed. Without touching the touchscreen, the resistance is equal to infinity.

Depending on the touch screen model, the resistance may fluctuate. These measurements were made on the touch screen of an I9+++ phone.

When is it time to change the touch screen?

It is time to change the touch screen in the following cases:

- if it does not respond to touch

- you found an "oily spot" on it (multi-color stains)

- unable to calibrate touch screen

- entering the message and selecting the English text input mode, try to put dots over the entire area, if dashes appear instead of dots, then it's time to change

- entering the service-miscellaneous-Touch Screen, try to put dots over the entire area, if green stripes appear instead of crosses - it's time to change

- if you try to click on the icon, the desktops scroll or the icons fall off (vertical shedding of icons in iPhone-like phones)

- if 5 minutes after the calibration you again do not hit the icon you click on

Touch screen

An input device, which is a screen that responds to touching it. There are many different types touch screens that operate on different physical principles. But we will consider only those that are found in mobile phones and other portable equipment.

How resistive touch screens work

Resistive touch screens come in two varieties, four-wire and five-wire. Consider the principle of operation of each of the types separately.

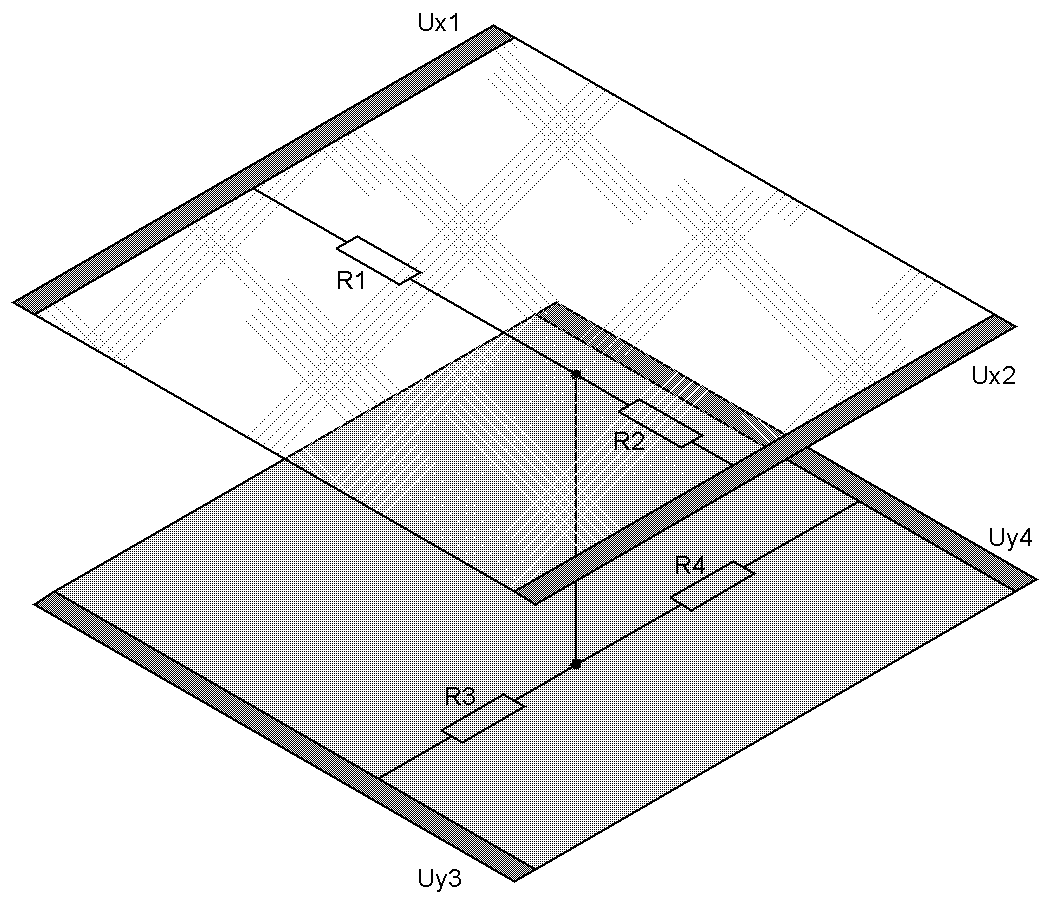

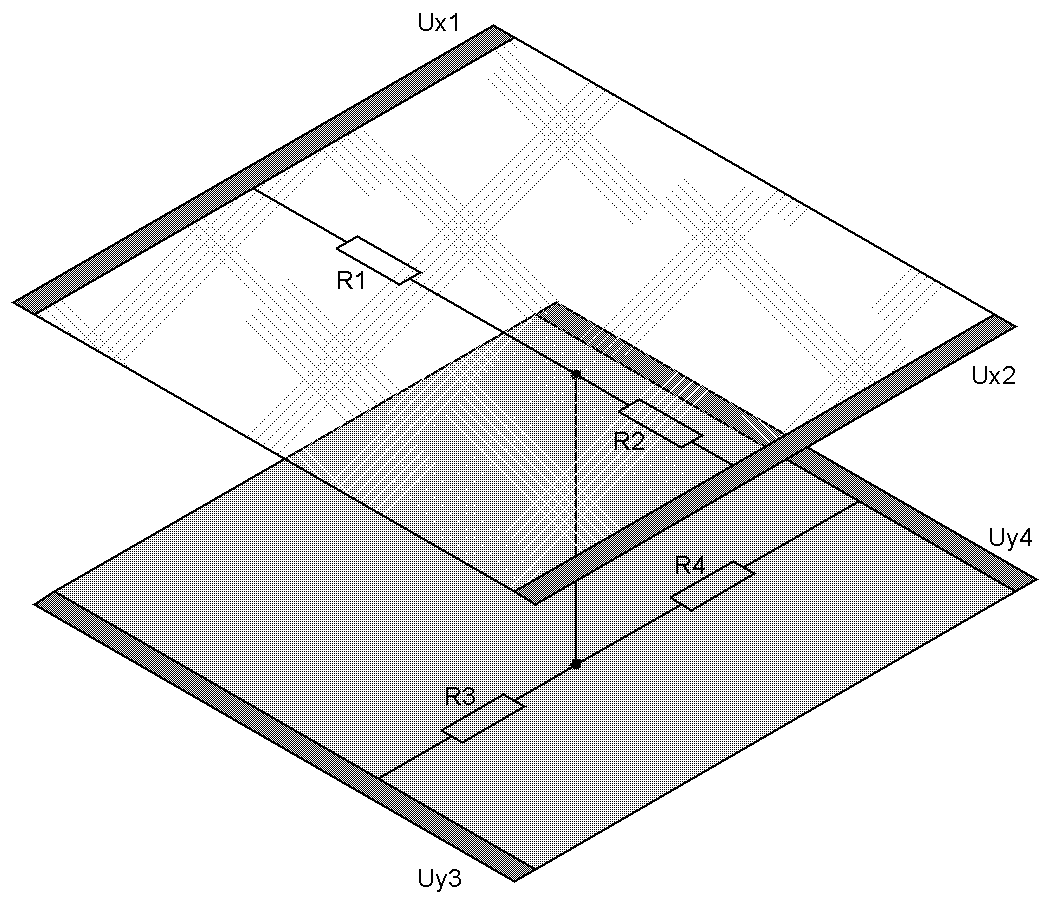

4-wire resistive screen

The resistive touch screen consists of a glass panel and a flexible plastic membrane. Both the panel and the membrane have a resistive coating. The space between the glass and the membrane is filled with micro-insulators, which are evenly distributed over the active area of the screen and reliably isolate conductive surfaces. When the screen is pressed, the panel and membrane are closed, and the controller, using an analog-to-digital converter, registers the change in resistance and converts it into touch coordinates (X and Y). In general terms, the reading algorithm is as follows:

1. A voltage of + 5V is applied to the upper electrode, the lower one is grounded. The left and right are short-circuited and the voltage on them is checked. This voltage corresponds to the Y-coordinate of the screen.

2. Similarly, + 5V and “ground” are supplied to the left and right electrodes, the X-coordinate is read from the top and bottom.

Five-wire resistive shield

The five-wire screen is more reliable due to the fact that the resistive coating on the membrane is replaced by a conductive one (the 5-wire screen continues to work even with the membrane cut through). The rear glass has a resistive coating with four electrodes at the corners.

Initially, all four electrodes are grounded, and the membrane is “pulled up” by a resistor to + 5V. The membrane voltage level is constantly monitored by an analog-to-digital converter. When nothing is touching the touch screen, the voltage is 5V.

As soon as the screen is pressed, the microprocessor detects the change in the membrane voltage and begins to calculate the coordinates of the touch as follows:

1. +5V voltage is applied to the two right electrodes, the left ones are grounded. The voltage on the screen corresponds to the X-coordinate.

2. The Y-coordinate is read by connecting both upper electrodes to +5V and both lower electrodes to ground.

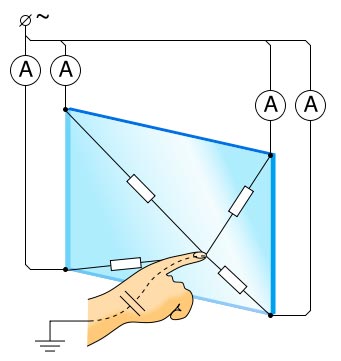

How capacitive touch screens work

A capacitive (or surface capacitive) screen takes advantage of the fact that an object of high capacity conducts alternating current.

A capacitive touch screen is a glass panel coated with a transparent resistive material (usually an alloy of indium oxide and tin oxide). Electrodes located at the corners of the screen apply a small alternating voltage (the same for all corners) to the conductive layer. When touching the screen with a finger or other conductive object, current leakage occurs. At the same time, the closer the finger is to the electrode, the lower the resistance of the screen, which means that the current strength is greater. The current in all four corners is recorded by sensors and transmitted to the controller, which calculates the coordinates of the touch point.

Earlier models of capacitive screens used direct current - this simplified the design, but with poor user contact with the ground, it led to failures.

Capacitive touch screens are reliable, with 200 million clicks (about 6 and a half years of clicks every one second), liquid-tight, and non-conductive pollution tolerant. Transparency at 90%. However, the conductive coating is still vulnerable. Therefore, capacitive screens are widely used in vending machines installed in a protected area. Not responsive to gloved hand.

The principle of operation of projected capacitive touch screens

A grid of electrodes is applied on the inside of the screen. The electrode together with the human body forms a capacitor; electronics measures the capacitance of this capacitor (applies a current pulse and measures the voltage).

The transparency of such screens is up to 90%, the temperature range is extremely wide. Very durable (the bottleneck is the complex electronics that process the clicks). Glass up to 18 mm thick can be used on POE, resulting in extreme vandal resistance. They do not react to non-conductive pollution, conductive ones are easily suppressed software methods. Therefore, projective-capacitive touch screens are used in vending machines installed on the street. Many models react to a gloved hand. AT modern models designers have achieved very high accuracy - however, vandal-resistant designs are less accurate.

POE react even to the approach of the hand - the threshold is set programmatically. Distinguish pressing with a hand from pressing with a conductive pen. Some models support multi-touch. Therefore, this technology is used in touchpads and multi-touch screens.

It is worth noting that due to differences in terminology, surface and projection-capacitive screens are often confused. According to the classification used in this article, iPhone screen is projective-capacitive.

Conclusion

Each of the types of touch screens has its advantages and disadvantages, for clarity, consider the table.

Touchscreens are of two types:

- resistive

- capacitive

Distinguish one from the other appearance simply. In capacitive there is a special microchip that captures the change in capacitance in a certain place when touched with a finger. Also, these touchscreens do not respond to touch with nails and any other objects, with the exception of special styluses for capacitive screens.

With an ordinary multimeter, you can only check resistive touchscreens, which are currently installed in 90% of phones.

Brief theory.

A resistive touchscreen electrically consists of two resistors (resistances) with a nominal value of usually 200-1000 Ohms

One resistor is applied to the base of the touchscreen (usually real glass), and the second resistor is applied to the film located above this base. When touching the sensor, the film comes into contact with the base, which causes electrical contact between the resistors, which leads to changes in the resistance between the resistors, by which the controller in the phone determines the coordinate of the touch point

Test Method

Based on the above, the verification technique boils down to measuring these two touchscreen resistances. They should not be abnormal, that is, less than 50 ohms and more than 1500 ohms. With mechanical damage, the coating layer is torn and the resistance will be infinitely large. Moreover, for this it is not necessary to break it, it is enough to press down strongly at the point of contact of the cable with the layers so that this contact moves away.

So, using the example of the above touchscreens, we need to take a multimeter, set it to the resistance measurement mode up to 2000 Ohm (2kOhm) and touch the probes to contacts 1 and 3. The device should show a value from 200 ohms to 1500 ohms. Similarly for 2 and 4 pins. At this stage, we are convinced of the integrity of the contours. But that is not all. Now it is necessary to check whether the layers are in contact by themselves without pressure being applied to them. To do this, set the multimeter to resistance mode up to 20 kOhm. Now we touch the 1st and 2nd contact and then the 2nd and 4th. The device should show nothing. But if you touch the touchscreen at this moment, the device will show some resistance, and it will change from a change in the place of touch. This is how the controller in the phone "learns" the coordinates of the touch point.

This is actually all.

PS. The contours of some touchscreens sometimes lead not to 1-3 and 2-4, but to 1-2 and 3-4 contacts of the cable. This should be taken into account when checking the touchscreen

Another article.

The touch resistive panel consists of two glued transparent plates, on the inner surface of which a conductive coating is applied - an indium oxide film. The bottom plate is usually made of glass, the top plate is a Mylar film coated with an anti-reflective layer. The lower glass part is attached to the display.

The upper Mylar film faces the user and is additionally coated with a chemical and scratch resistant layer.

Between the plates there is an insulating layer, which is a grid of microscopic, chemically etched glass pillars on the bottom surface. When pressing on the upper film, a local deflection and a closure of the two conductive layers occur. The controller, when scanning the sensor tires, determines the coordinates of the pressure point.

In most cases, 4-wire touch panel designs are used. Two equivalent conducting surfaces are used here: one surface determines the position of the coordinate along the X-axis (X- / X+), the other - along the Y-axis (Y- / Y+).

Scanning is performed in two phases. In the first phase, a test voltage is applied to the electrodes of the conductive plate X, and the conductive surface of the plate Y serves to remove the potential formed by the resistive divider at the point of contact. During the conversion process, the controller obtains a value proportional to the X-coordinate. In the second phase, a symmetrical procedure occurs and the second Y-coordinate is obtained.

In a 4-wire circuit, shunting metal end strips applied with silver or copper paste are used to evenly distribute the potential along the conductive film. These stripes are visible along the edges of the touchpad, and the space inside them is called the visible area of the sensor.

Resistivity of conductive coatings - from 220 to 500 Ohm/sm.kv. for the top film and from 600 - 850 Ohm/sm.kv. for glass substrate.

Before installing the touchscreen, it is recommended to check with an ohmmeter. If the check was successful, then it is necessary to check the sensor by connecting it to the connector or by spot soldering if the device does not have a connector. Protective stickers do not need to be removed. Such a measure will facilitate the exchange of the sensor in the event of a marriage. There is a possibility that the cause of the malfunction was not in the touch panel (bad contact, short circuit, broken tracks, controller malfunction, software failure).

Checking with an ohmmeter consists in measuring the resistance for each coordinate (pins 1-3 and 2-4, respectively). The device will show a resistance value of several hundred ohms. The resistances in coordinates differ by 1.5 - 3 times.

To check for a short circuit, the ohmmeter probes are connected to the contacts of different coordinates. In this case, the ohmmeter will show infinity, and when you touch the working plane of the sensor with your finger, the device will show some resistance.

If cracks appear on the glass substrate, the sensor will not work, or it will work partially. In this case, it should be replaced with a new one.

There are several ways to determine the working surface:

- the adhesive layer around the perimeter of the sensor is always located on the bottom, which is adjacent to the display

- marking on the side of the working surface is always read from left to right

- the lower part of the sensor in most cases is glass, if you lightly tap it with a metal object, the sound will be sonorous, and if you tap on the working side, the sound will be muffled

On some sensors, there is no adhesive layer initially; in this case, a thin 2-sided adhesive tape is used.

There are sensors without a glass substrate, using a plastic material.

If, after connection, the sensor does not work adequately (mirrored), this may mean that the conductors of some coordinate are confused in places. At different manufacturers alternation of coordinate contacts on the loop do not match. The issue is solved by the correct wiring of the conductors, or by calibration (with a certain skill).

On our website, in the description of common sensors, the sequences of contacts on the cables are indicated.

The following bus alternation is considered the basic sequence: X1 - Y1 - X2 - Y2.

On some sensors, the conductors on the cable are located crosswise, in this case, the alternation of contacts in coordinates may differ from the standard one and the sensor will not work with a direct replacement! In such cases, it is necessary to find out the bus wiring on the cable and solder the conductors in accordance with the native circuit. Keep this in mind when checking and replacing!!!

Now many modern mobile devices, such as mobile phones, smartphones, tablet computers, eBooks equipped with a touch screen. Such a touch screen, or touchscreen (from the English touchscreen) is an input-output device that registers touches to it and tracks the coordinates of the touch point, which subsequently correlates with the control element (interface) located at this point.

The need for a touchscreen arises when miniature gadgets need to be able to enter data without traditional devices such as a push-button keyboard and mouse. Agree, it is much more convenient to control a tablet or smartphone using a touch screen, otherwise you would have to connect additional data input devices to them, which will affect the mobility of such devices. In addition, the touchscreen is no longer a luxury, and is available to most users. mobile devices.

Although the touch screen operation scheme described above is the same, it is implemented in different ways.

There are various technologies for building touchscreens. Let's consider them in more detail.

Resistive technology

Resistive screen device

Resistive screen device

The basis of the touch screen, built on resistive technology, is a rigid glass base and a flexible outer layer. Both of these surfaces are coated with a layer of material that conducts electric current. Between them is placed a layer that isolates one surface from another in idle mode. When you press the screen, the conductive layers are closed, and the controller, using a special algorithm, determines the coordinates of the touch point and correlates it with the location of the interface elements.

This type of screen is the cheapest, and therefore the most common among all types of mobile devices. Unpretentious and quite reliable in operation. Responds to all types of mechanical pressing: stylus, finger, coin, etc.

There are also disadvantages. The most significant of them is the low light transmission of such screens, reliability depends on the mechanical strength of the flexible outer layer, which can be damaged by a sharp object, and the inability to register several clicks at once (multi-touch). Also, despite the large declared number of clicks on one point of the screen (35 million clicks), in this parameter, the resistive display loses to its counterparts built on other technologies.

capacitive technology

The principle of operation of the capacitive screen

The principle of operation of the capacitive screen

This technology is based on the fact that the human body has a certain electrical capacity. Such a screen is based on a glass panel coated with a conductive coating. A small voltage is applied to this coating at the corners of the screen. At the moment a finger touches such a screen, current leakage occurs at the touch point, the controller registers the amount of leakage current in the corners of the screen and calculates the coordinates of the touch point.

The advantages of such screens are extended resource (up to 200 million touches), the coating has good light transmission.

Among the shortcomings, it should be noted that such a screen does not support the control of the stylus or gloved hands due to the peculiarities of its technology.

Projected capacitive technology

Projection-capacitive screen device

Projection-capacitive screen device

Such a touch screen consists of a glass panel with a mesh of electrodes applied to its back. At the moment a finger touches such a screen, the electrode on the reverse side of the screen, together with the finger and a layer of dielectric glass, form a capacitor through which an alternating current will flow. The controller, when periodically polling the grid of electrodes, detects the presence of current in them and measures the capacitance.

Advantages - high transparency of the screen, durability, can even react to a raised finger or a finger in a glove.

Disadvantages - such screens are quite expensive and require complex electronics for their operation, which reduces the reliability of the entire complex.

Due to their good anti-vandal resistance, such screens are mainly used in ATMs and payment terminals.