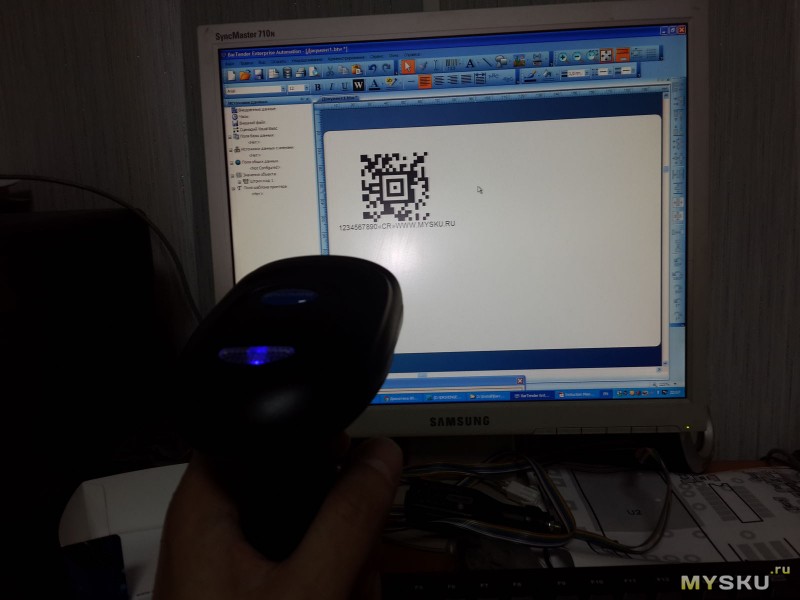

I decided to slightly automate my work and ordered a barcode scanner for this. But since I needed a scanner that could read two-dimensional codes(for example, QR codes), then cheap scanners, unfortunately, were eliminated immediately. And I chose the cheapest one that could do 2D from a seller with a good rating.

Briefly - ok :) More details - a short review under the cut.

Lots of photos without spoilers!

Firstly, I want to immediately apologize for the quality of the photos - I did the review at work, took pictures with my phone. And for the mess on the table - all the other tables are occupied, and this one takes too long to clean up :)

The first thing I want to draw your attention to is the delivery time - 10 days. 10 days! From the date of order - January 11 - to the date of receipt - January 21... On the 13th it was delivered to the post office in China, on the 18th it went through customs, and on the 21st it was already in my post office. Historical event, damn it - from customs to receipt only 3 days.

It arrived in a standard gray package containing an unpresentable box wrapped in one layer of bubble wrap:

The complete set is also very ascetic - the scanner itself, a cable, a disk and a clip for disconnecting the cable from the scanner:

Characteristics from the seller's page:

Sensor resolution: 960*640

Able to read:

1D:

- EAN-8

- EAN-13

- UPC-A

- UPC-E

- Code 39

- Code 93

- Code 128

- EAN128

- Codebar

- industrial 2 of 5

- Interleave 2 of 5

- Matrix 2 of 5

- postal code

- etc..

- PDF417

- Chinese-Sensible Code

- etc.

Speed: 230 /sec

Interface: USB2.0

Equipment coating: Gold-Plated

Optics level: V-V1 (Aerial Cameras)

Indicators: buzzer and two-color indicator: red - power, blue - recognition successful

Terms of Use:

Falls: allowed to free fall from 2 m 300 times (?)

Protection: IP54

Operating temperature: from -20 to +55 degrees

Storage temperature: -40 to 65 degrees

Operating humidity: 5% - 95% non-condensing

Storage humidity: 5% - 95% non-condensing

Light level: 0-120000LUX

Physical parameters:

Weight: net 157 grams, gross 349 grams

Dimensions: packing 190mm×115mm×80mm

Electrical parameters:

Operating voltage: 5V

Current consumption: 280mA

Power: 1.4W

Safety standard: EN60950-1

EMC: EN55022 EN55024

The scanner connects to the computer via USB. On the side connecting the cable to the scanner, 10-pin RJ50 connector (10P10C):

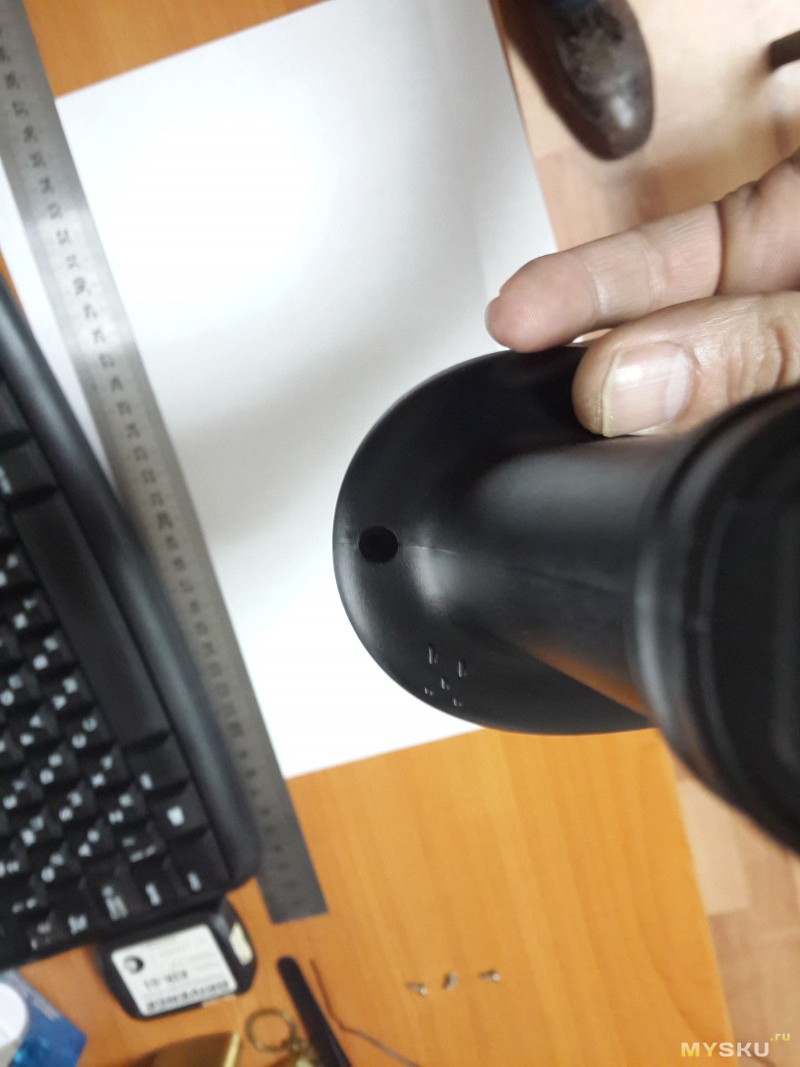

This connector snaps into place inside the scanner handle and to remove it you need to insert a paperclip or toothpick into the hole on the side of the handle and press down. When inserted, it gives the impression of a monolithic structure:

The scanner's operation is not based on scanning with a laser beam, but on photographing and recognizing barcodes on the resulting images. According to those According to the seller, he does this 200 times per second, but according to his work it doesn’t seem very similar :) More likely closer to 2-10 times, since scanning takes approximately 0.1 to 0.5 seconds, depending on the conditions and type of code .

Here is his “face”:

In the middle is the matrix lens, on the right is the backlight LED, on the left is the “targeting” laser lens.

The scanner itself is small as standard and fits quite comfortably in your hand:

Cable length 198 cm including connectors. The wire is quite thick, but soft.

When connected, it is detected by the computer as an HID keyboard, without requiring any drivers. As soon as the scanner recognizes a barcode, it sends the computer the text sequence recognized in the code. Can add Tab, Enter, or both at the end of the sequence. This and several other settings are carried out through recognition of service barcodes from the manual.

If necessary, you can switch it to virtual COM port mode (also with a service barcode), but I have not tried this mode; I don’t need it. For this mode you will need to install drivers.

I don’t know what’s on the disk, since I don’t have it. CD-ROM drive:) Instead, I just found on the Internet what seems to be the manufacturer of this scanner (Yoko). And although there is no such model on his website, there is a twin brother, the drivers and manual from which I downloaded. Both came up. I attached the link at the end of the review.

Recognition is carried out only by pressing a button, automatic mode I couldn't get it out of him. The service barcode that includes it is not accepted by the scanner. However, I don’t need this mode :)

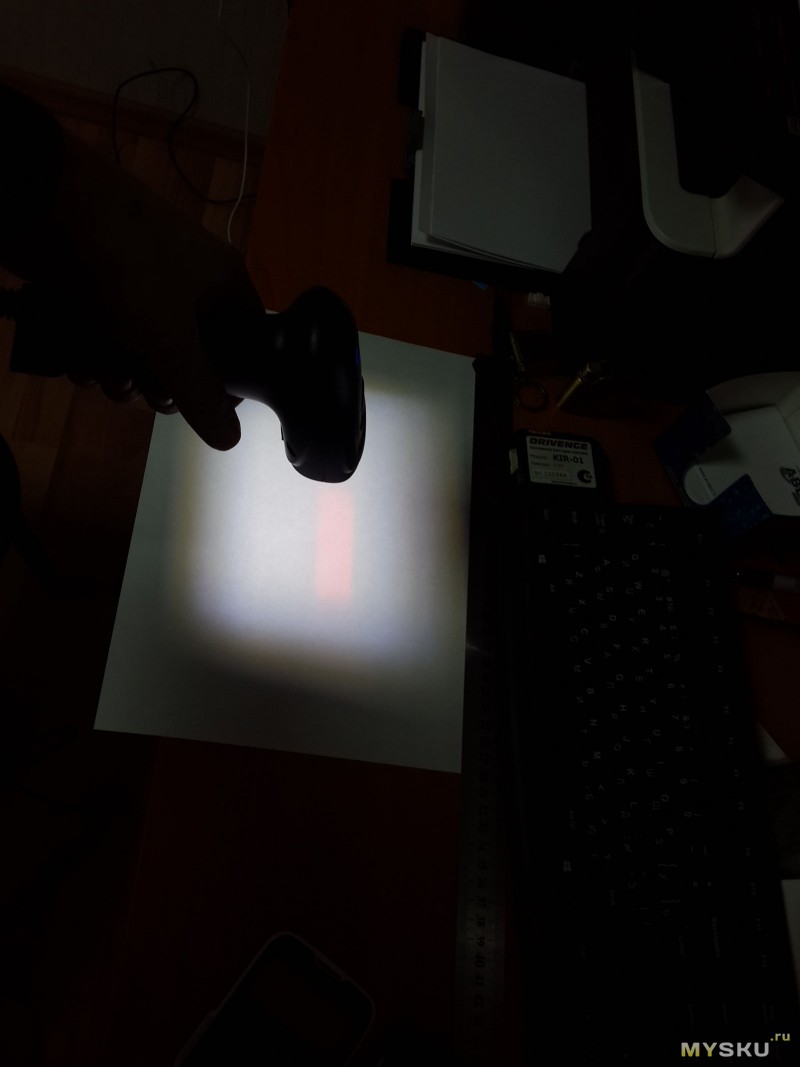

The backlight is quite bright. Against the background of the area illuminated with white light, you can see the “targeting” strip, which the manufacturer recommends aiming at the code. Here is a “beamshot” on an A4 sheet from a distance of about 10 cm:

The reddish aiming strip is clearly visible. However, the scanner recognizes barcodes that go beyond this band, but not too far. A much larger area is illuminated than is visible to the sensor.

As soon as the scanner recognizes the barcode, the backlight turns off and for the next recognition you need to release and press the button again. If it fails to recognize anything within about 10 seconds, the backlight turns off and the scanner stops trying to see anything until the button is pressed again.

The indicator on top lights up constantly blue and winks red at the moment of successful recognition. At the same time, the buzzer beeps. The sound is high, quite loud, but not piercing, after the thirtieth scan you won’t have the desire to smash it against the wall :)

I like to take apart everything that I haven’t taken apart before, and I haven’t taken apart scanners yet :)

Disassembly

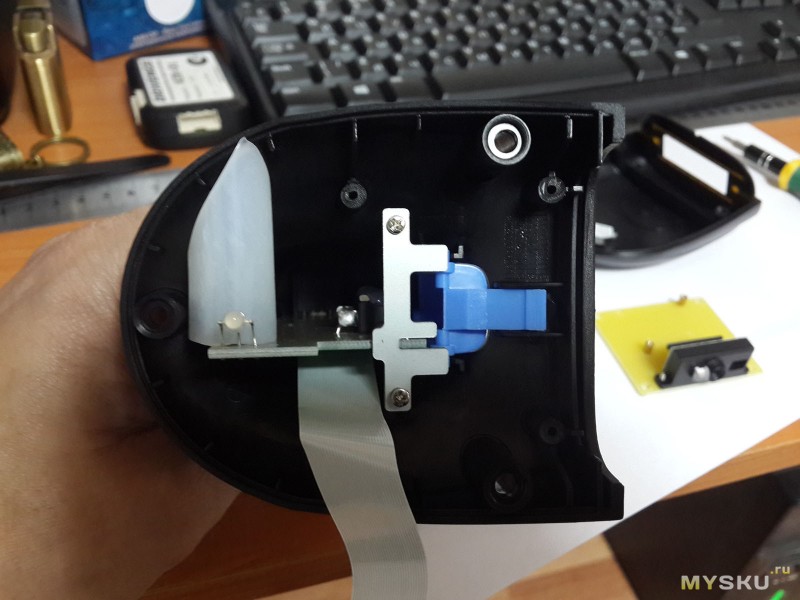

The case consists of two parts - the top cover and everything else. Everything is held together by three screws:

Having unscrewed them and removed the cover, we will see a small scarf and a sensor unit:

All this is screwed to a textolite plate, which in turn is screwed to the body. The Chinese are well-known economists, and here it is clear - that the control board and the textolite plate have only two fasteners instead of four. We saved two bolts with stands and two screws...

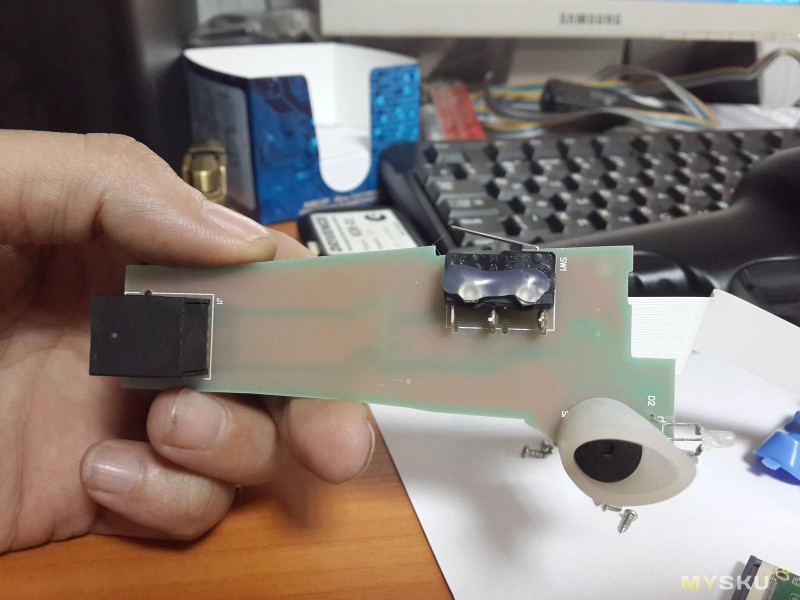

Disconnect the short cable, unscrew the board from the plate and the plate from the body. There is another circuit board in the handle. It and the button are held in place by a metal bracket:

Unscrew it and take everything out:

On the board of the handle there is only a button, a connector and a small buzzer harness:

There are 4 chips on the control board, as promised in the seller's description (Four-chip Dealing Technology Exclusively) :) The markings are somehow incomprehensible, most likely this is a specialized custom chip, memory and something else :) There is nothing interesting, so putting it back together :)

The settings in the manual are not very numerous, but for basic work it should be enough:

- switching to virtual COM port mode and back to HID keyboard mode

- disable recognition of service codes (except for the reverse activation code)

- reset to factory settings

- preservation and restoration of some custom settings

- turning on and off the automatic recognition mode (this scanner does not accept these codes)

- enable or disable the mode of reading codes from the screen of a smartphone or computer (in this mode, the scanner periodically turns off and turns on the backlight when searching for a code - turns it off so that there are no reflections on the screen, turns it on so that you can scan paper barcodes)

- turning focus mode on and off (I didn’t understand what it was and what it was for)

- setting up a suffix - an addition sent to the computer after the code itself, you can enable the addition of a tab, or a line feed, or both, or disable all

Well, the most important thing is what this scanner can recognize.

I have had the Bartender program installed for a long time - an excellent thing for working with labels, which knows a bunch of types of barcodes - 67 of them, can print them and display them in the designer. I used this program to test the scanner, displaying different types barcodes and trying to scan them.

The scanner was able to recognize 31 types. Below the spoiler are their images and names.

Recognizable barcodes

2D-Pharmacode:

Aztec Code:

Circular Code 39

Circular Code 93

Circular Code 128

Codabar (NW-7)

Codablock F

Code 32 (Italian pharmacode)

German Post Identcode

Deutsche Post Leitcode

EAN/JAN-8

EAN/JAN-13

GS1 Composite

GS1 Databar (RSS)

GS1 DataMatrix

GS1 QR Code

Industrial 2-of-5

Interleaved 2-of-5

ITF-14

Matrix 2-of-5

OPC (Optical Product Code, VCA)

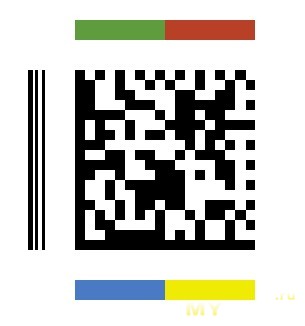

PDF417

QR Code

Standard 2-of-5 (ITA)

UPC-A

UPC-E

All codes were read directly from the monitor.

Advantages:

- price:) Offline they are much, much more expensive, many times…

- I don’t know anymore, because... I haven’t worked with scanners before :)

There are disadvantages:

- the button is too soft and works at the very beginning of the move, I don’t really like it

- does not recognize well on shiny surfaces, although if you scan at a slightly angle it’s fine

- automatic recognition is not configured, although not everyone needs it

- does not recognize all 67 types of codes :)))

Bottom line: a normal scanner, recognizes confidently and fairly quickly, and is inexpensive.

PS: I plan to work with the following labels:

In the comments, a question arose about how this scanner copes with identifying one of many closely spaced codes. I'm posting a video of the test drive :)

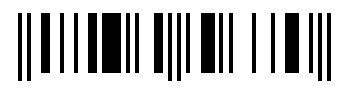

1. Linear barcode (Code 128), barcode size 29x13 mm, the gap between them is 10 mm horizontally and 8 mm vertically:

2. 2D barcode (PDF417), barcode size 33x7mm, the gap between them is 6.5 mm horizontally and 2.5 mm vertically:

3. 2D barcode (QR Code), barcode size 13.5x13.5 mm, the gap between them is 2 mm horizontally and 2 mm vertically:

I'm planning to buy +16 Add to favorites I liked the review +33 +55

We apologize to our readers, but even in such an area as modern commercial equipment there are subjects and topics that cannot be discussed without computer terminology. There is no other choice but to get used to and master this new language, in which we all, it seems, will have to express ourselves and explain ourselves to each other more and more if we want to be in the civilization that we ourselves are creating. As far as possible, we have provided some terms in this publication with explanatory translations and explanations in parentheses.

Two-dimensional barcodes (hereinafter: 2D, English "2 dimention"s") are the latest developments in the field of barcoding. The name 2D is used to describe any barcode that encodes information by relying on more than just vertical bars and spaces. There is two types of 2D codes: stacked liner and matrix. "Stacked liner codes typically increase the information stored in a barcode by placing the barcodes one on top of the other. Code 16K, Codablock and Code 49 barcodes are early members of this family. These barcodes offer reasonable density and average information capacity (up to 144 characters), but are inferior to some of the latest 2D barcodes in that they do not provide error correction to allow even partially damaged barcodes to be read correctly.

The main reason for the emergence of new technologies in this area is that the consumer wants to label and store everything large quantity information. He is no longer satisfied with traditional one-dimensional barcodes, which typically contain up to 32 characters. These barcodes are often called “license plates”, since the information stored in such codes is only a key or a link to an external database; the code itself does not contain comprehensive information about the product. This technology became widespread at one time. Meanwhile, developers of autoLD solutions (in Russian: self-identification) inevitably came to the idea of 2D codes, as the requirement to store ever-increasing amounts of information in ever-smaller areas was constantly increasing.

2D barcodes are essentially portable information files of high density and capacity, and provide access to large volumes of information without reference to an external database. That is, 2D barcoding technology allows you to store all the necessary information in the barcode itself. 2D barcodes have a predominantly matrix form and do not use traditional bars/spaces to encode information. Instead of standard bar width detection technology, matrix barcodes use an on/off design (ie, yes-no or one-zero) to encode information. There are many varieties of 2D barcodes (for example, PDF417, MaxiCode, Dotamatrix).

PDF417

PDF417 - "stacked linear" - technology developed by Symbol Technologies. This barcode is capable of storing extremely a large number of information (up to 25,000 characters), has a high density and provides good error correction. PDF417 allows you to decode binary code, which means that a photo, fingerprint, or any other type of data can be encoded in such a barcode. This barcode is ideal for use in identification cards, for marking transported goods, for EDI, etc.

MAXICODE

Maxicode is developed by United Parcel Service. Created for the needs of sorting goods, this barcode is easy to scan and, importantly, can be applied to curved surfaces. It is easily recognized by the hexagonal elements that make up its base. DATAMATRIX Given the increased demands on barcode capacity, ID Matrix of Clearwater (Florida) developed the Datamatrix code specification. This code fully meets these requirements and also provides error correction. It can be applied not only to small labels, but also to the product itself, if it has sufficient density for this.

PRINTING 2D barcodes

Most printers produced today are capable of printing in both Direct Transfer and Thermal Transfer modes. With direct thermal printing, the image is applied to special thermal labels. However, it should be kept in mind that this type of printing is not durable. The image can greatly lose quality after just a week when exposed to direct sunlight, and even faster if there are fluorescent lamps nearby. Thermal transfer printing is carried out on regular paper or any other labels; for this, replaceable cartridges with special thermal film are used. Typically, labels produced using thermal transfer printing differ good quality and are significantly less susceptible to moisture and sunlight. Almost all modern printers that can print regular barcodes are also capable of printing 2D barcodes.

CONVEYOR SCAN

The first models of 2D scanners were developed, in particular, for the needs of high-speed scanning on a conveyor belt. A conveyor belt can move at speeds of up to 500 feet per second (approx. 150 m), and no large warehouse or distribution center can do without such equipment today. 2D scanners are capable of scanning hundreds of packages without reducing the speed of their transportation on the conveyor. High-speed scanning systems are offered by Computer Identics/RVSI.

2D BARCODE READERS

2D barcode readers, unlike ordinary barcode scanners, first capture their image, then analyze the resulting image, and only then extract and decode the barcode. Devices that use video image analysis are required to effectively read matrix codes, but can also read regular barcodes. Video analysis technology opens up possibilities for reading signatures, optical recognition characters, etc.

HAND SCANNERS

Some vendors include video analysis in their handheld scanners. One such company, Welch Allyn, offers its customers the IMAGETEAM 4400 device, which reads both MaxiCode and conventional barcodes and has additional support for PDF417 and Datamatrix codes.

CONCLUSION

As we can see, 2D barcoding can significantly expand the scope of application of barcodes. For example, use them in ID cards, applied to medicines and anywhere that very small labels are required, etc. Due to the large amount of information contained in a barcode, the described technology is increasingly used in industry and where conventional barcodes no longer meet the increased requirements for the completeness of the information provided. It is clear that the demand for such technology and related equipment will grow.

01.03.2016

Choosing a barcode scanner can be a daunting task if you don't have a lot of experience. This short review what you should know when choosing a barcode scanner.

1D or 2D?

The first question you should ask is what type of barcode you will be scanning: 1D or 2D. This is important because a 1D scanner cannot scan 2D barcodes, although 2D scanners can scan 1D barcodes. Therefore, if you decide to buy a 1D scanner, then rest assured that you will not need to read 2D barcodes.

Linear barcode standards:

EAN – European (EAN-8 consists of 8 digits, EAN-13 - 13 digits are used),

UPC (UPC-A, UPC-E),

Code39

Code128(UPC/EAN-128),

Codabar

2D barcode standards:

Aztec Code;

Data Matrix;

MaxiCode;

PDF417;

QR code;

Microsoft Tag

Barcode scanners also differ in the type of reading element:

- LED (CCD)

- Laser

Laser scanners barcode A low-power laser is used as a reading element. Such scanners are very popular because they can scan a barcode at any tilt of the label. But the disadvantage of such scanners is their inability to read shiny, laminated and other glossy surfaces.

Linear Image Scanners is the most advanced linear barcode reading technology available today. This type of scanner has a wide and clearly focused backlight, thanks to which the scanner can read a wider barcode strip and cope well with low-contrast and damaged codes. Such barcode scanners have a high reading speed (from 270 to 450 scans/sec) and a shock-resistant design. And also linear photo scanners can read barcodes at a distance of up to 2 meters.

Matrix photo scanners (Area Image) - the operating principle of scanners that have this type of reading element is that the barcode is photographed during scanning and, using a smart algorithm, this photograph is decoded and processed by the scanner. The matrix barcode scanner can scan all known types of barcodes: linear two-dimensional, composite barcodes. It can also read barcodes in any orientation relative to the code. It can be used in any lighting.

Barcode scanners are also divided into:

- Hand wired

- Handheld wireless

- Tabletop

- Built-in

Handheld Wired Barcode Scanners are the most common and use laser or photo elements. These scanners have a handle that is very comfortable to use. Such scanners connect to a computer or POS systems via USB or keyboard port (KB)

Wireless scanners barcode can be used away from a computer and are convenient to use if you need to scan an item that is difficult to transport. A mandatory attribute of such scanners is the interface WiFi connections, Bluetooch or radio channel. Cordless scanners also have a battery, the charge of which limits how long it can operate without recharging.

Desktop Barcode Scanners – as a rule, they have a large scanning area, which allows you to quickly scan a large number of products. This fact makes them an ideal option for retail, where fast customer service and the absence of queues at the checkout are important factors.

Embedded barcode scanners – such scanners are built into the tabletop. These types of scanners have increased scanning speed. Therefore, they are often used in large supermarkets where increased scanning speed is required.