Tablets, many smartphones, as well as monitors, displays on household appliances are equipped with touch screens. This technology pleases, firstly, with its attractive design, and secondly, with its functionality and simplicity. In addition, now there is no need to waste space on the placement of buttons, which is also very convenient. Read about the types of screens, their structure, principles of operation, pros and cons in our article.

The most popular types of sensors

Resistive sensors

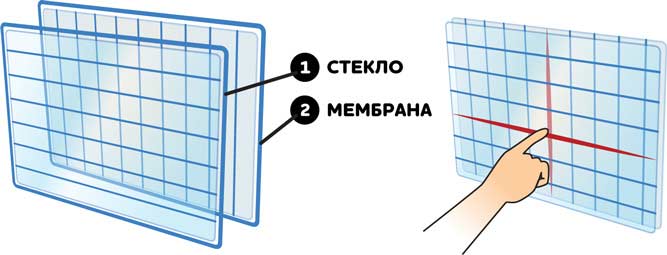

The resistive sensor consists of a plastic membrane (comes first) and a panel made of glass (comes the second layer). A microinsulator is laid between these layers, designed to protect conductive surfaces from each other. Electrodes are located on the surfaces of the layers (in the first layer they run horizontally, in the second - vertically). By pressing the screen, you provoke the closure of the layers, a special sensor reads your pressing and converts it into a signal that is transmitted to the processor. As a result, the screen responds to the task set by your touch - for example, it starts a video, opens a document, and so on.

This technology is considered quite simple, and therefore not too much money is spent on the manufacture of resistive screens. As a result, products with them often end up in the budget price segment, which is the main advantage of technology with resistive screens. Resistive display technology is presented in in large numbers and assortment. Among the disadvantages of this type of sensors are the lack of support for multi-gestures, poor visibility in the sun / in bright light, low wear resistance, and low accuracy.

Capacitive sensors

This technology is more advanced - it supports multi-touch, has decent visibility in bright light and better wear resistance, more high level accuracy. Among the disadvantages are the higher price of devices with capacitive screens, a negative reaction to exposure to liquids.

How does it work touch screen of this type? The key role here is played by electrodes located in the corners of the display and transmitting to each other variable flows of electricity. As a result, a kind of current grid is formed. By pressing on the screen, a person shifts the direction of the current, which allows the system to determine the place of pressing and, accordingly, calculate and execute the required command. The human body in this case, together with the screen itself, act as current conductors. The display consists of glass coated with a resistive material to ensure efficient electrical contact.

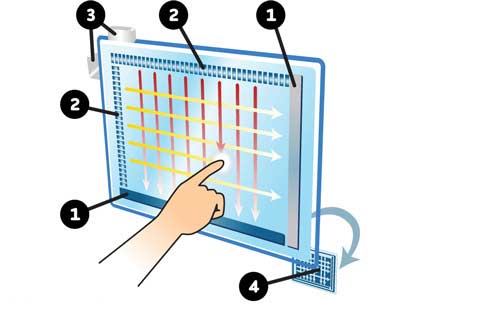

infrared sensors

The screen frame (made of glass) includes receivers and emitters of infrared rays. When working, they form an infrared grid on the surface of the display. By clicking on the screen, we will block access to certain beams - the system will calculate this place and consider the corresponding task that it will need to perform.

Among the disadvantages are not very high accuracy (especially in bright light), "fear" of pollution and the high cost of products with infrared displays. Among the advantages - good visibility in the sun, durability.

Less popular types of sensors

Matrix sensors

The matrix system is similar to how the sensor works in resistive display models. Only vertical current conductors are applied to the membrane, and horizontal conductors are applied to the glass. Pressing causes a closure, which the system calculates and then converts into the execution of a particular task.

Matrix screens are rarely used today because they are considered very inaccurate and therefore unproductive.

Screens on surface-acoustic waves

Piezoelectric transducers are built into different corners of the glass panel. Along the perimeter of the display are sensors that receive and reflect signals. A special controller provides a high frequency of signal generation. Pressing the display provokes the execution of a task.

An input device, which is a screen that responds to touching it. There are many different types touch screens that operate on different physical principles. But we will consider only those that are found in mobile phones and other portable equipment.

How resistive touch screens work

Resistive touch screens come in two varieties, four-wire and five-wire. Consider the principle of operation of each of the types separately.

4-wire resistive screen

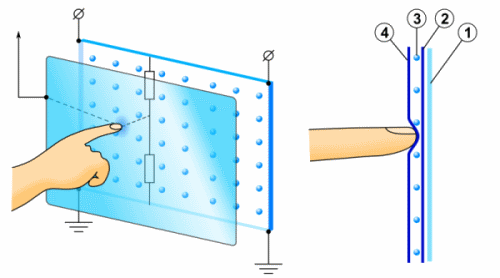

How the 4-wire resistive touch screen works

The resistive touch screen consists of a glass panel and a flexible plastic membrane. Both the panel and the membrane have a resistive coating. The space between the glass and the membrane is filled with micro-insulators, which are evenly distributed over the active area of the screen and reliably isolate conductive surfaces. When the screen is pressed, the panel and membrane are closed, and the controller with analog to digital converter registers the change in resistance and converts it into touch coordinates (X and Y). In general terms, the reading algorithm is as follows:

- A voltage of + 5V is applied to the upper electrode, the lower one is grounded. The left and right are short-circuited and the voltage on them is checked. This voltage corresponds to the Y-coordinate of the screen.

- Similarly, + 5V and “ground” are supplied to the left and right electrodes, the X-coordinate is read from the top and bottom.

Five-wire resistive shield

The five-wire screen is more reliable due to the fact that the resistive coating on the membrane is replaced by a conductive one (the 5-wire screen continues to work even with the membrane cut through). The rear glass has a resistive coating with four electrodes at the corners.

How the 5-wire resistive touch screen works

Initially, all four electrodes are grounded, and the membrane is “pulled up” by a resistor to + 5V. The voltage level on the membrane is continuously monitored analog-to-digital converter. When nothing is touching the touch screen, the voltage is 5V.

As soon as the screen is pressed, the microprocessor detects the change in the membrane voltage and begins to calculate the coordinates of the touch as follows:

- +5V voltage is applied to the two right electrodes, the left ones are grounded. The voltage on the screen corresponds to the X-coordinate.

- The Y-coordinate is read by connecting both upper electrodes to +5V and both lower electrodes to ground.

How capacitive touch screens work

A capacitive (or surface capacitive) screen takes advantage of the fact that an object of high capacity conducts alternating current.

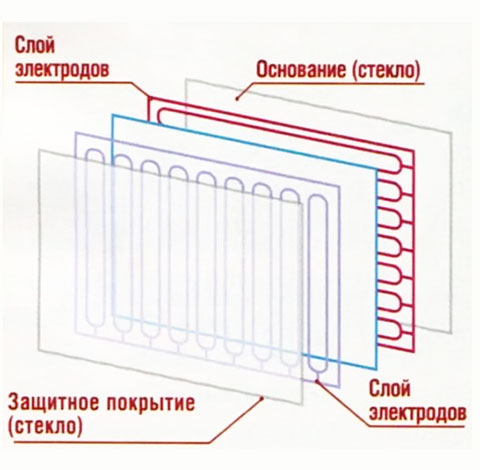

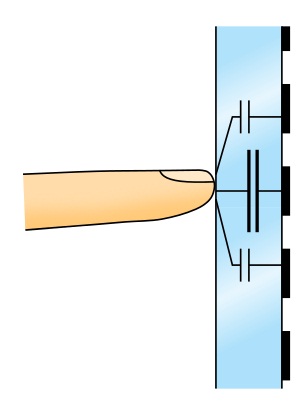

The principle of operation of the capacitive touch screen

A capacitive touch screen is a glass panel coated with a transparent resistive material (usually an alloy of indium oxide and tin oxide). The electrodes located at the corners of the screen apply a small amount of energy to the conductive layer. AC voltage(the same for all corners). When touching the screen with a finger or other conductive object, current leakage occurs. At the same time, the closer the finger is to the electrode, the lower the resistance of the screen, which means that the current strength is greater. The current in all four corners is recorded by sensors and transmitted to the controller, which calculates the coordinates of the touch point.

Earlier models of capacitive screens used direct current - this simplified the design, but with poor user contact with the ground, it led to failures.

Capacitive touch screens are reliable, with 200 million clicks (about 6 and a half years of clicks every one second), liquid-tight, and non-conductive pollution tolerant. Transparency at 90%. However, the conductive coating is still vulnerable. Therefore, capacitive screens are widely used in vending machines installed in a protected area. Not responsive to gloved hand.

The principle of operation of projected capacitive touch screens

A grid of electrodes is applied on the inside of the screen. The electrode, together with the human body, forms a capacitor; electronics measures the capacitance of this capacitor (applies a current pulse and measures the voltage).

The principle of operation of the projected capacitive touch screen

The transparency of such screens is up to 90%, the temperature range is extremely wide. Very durable (the bottleneck is the complex electronics that process the clicks). Glass up to 18 mm thick can be used on POE, resulting in extreme vandal resistance. They do not react to non-conductive pollution, conductive ones are easily suppressed software methods. Therefore, projective-capacitive touch screens are used in vending machines installed on the street. Many models react to a gloved hand. IN modern models designers have achieved very high accuracy - however, vandal-resistant designs are less accurate.

POE react even to the approach of the hand - the threshold is set programmatically. Distinguish pressing with a hand from pressing with a conductive pen. Some models support multi-touch. Therefore, this technology is used in touchpads and multi-touch screens.

It is worth noting that due to differences in terminology, surface and projection-capacitive screens are often confused. According to the classification used in this article, the iPhone screen is projected-capacitive.

Conclusion

Each of the types of touch screens has its advantages and disadvantages, for clarity, consider the table.

| Resistive 4-wire | Resistive 5-wire | capacitive | Projected-capacitive | |

|---|---|---|---|---|

| Functionality | ||||

| gloved hand | Yes | Yes | No | Yes |

| solid conductive object | Yes | Yes | Yes | Yes |

| solid non-conductive object | Yes | Yes | No | No |

| Multitouch | No | Yes | Yes | Yes |

| Force measurement | No | No | No | Yes |

| Ultimate transparency, % | 75 | 85 | 90 | 90 |

| Accuracy | Height | Height | Height | Height |

| Reliability | ||||

| Lifespan, million clicks | 10 | 35 | 200 | ∞ |

| Protection against dirt and liquids | Yes | Yes | Yes | Yes |

| Vandalism resistance | No | No | No | Yes |

The article was written based on the materials of the site

Nowadays, no one doubts that the touch screen on your phone is a convenient thing. Such displays are used to create a variety of devices - tablets, mobile phones, readers, reference devices and a bunch of other peripherals. The touch screen allows you to replace numerous mechanical buttons, which is very convenient, since in this case they combine both the display and a high-quality input device. The level of reliability of devices is significantly increased, because there are no mechanical parts. Currently, touch screens are usually divided into several types: resistive (there are four-, five-, eight-wire), projective-capacitive, matrix-capacitive, optical and tensometric. In addition, displays can be created on the basis of surface acoustic waves or infrared rays. There are already several dozen patented technologies. Nowadays, capacitive and resistive screens. We will consider them in more detail.Resistive screen.

The simplest type is a four-wire, which consists of a special glass panel, as well as a plastic membrane. The space between the glass and the plastic membrane must be filled with micro-insulators, which can reliably isolate conductive surfaces from each other. Electrodes, which are thin plates made of metal, are installed over the entire surface of the layers. In the back layer, the electrodes are in a vertical position, and in the front layer, in a horizontal position so that coordinates can be calculated. If you press the display, the panel and the membrane will automatically close, and a special sensor will perceive the pressing, converting it into a signal. Eight-wire displays are considered the most advanced type, which have a high level of accuracy. However, these screens are characterized by a low level of reliability and fragility. If it is important that the display is reliable, it is necessary to stop the choice on its five-wire form.

1 - glass panel, 2 - resistive coating, 3 - microinsulators, 4 - film with conductive coating

matrix screens.

The design is similar to a resistive display, although it has been simplified. Vertical conductors were specially applied to the membrane, and horizontal conductors were applied to the glass. If you press the display, then the conductors will definitely touch, close crosswise. The processor can keep track of which wires are shorted, and this helps to detect the coordinates of the click. Matrix screens cannot be called high-precision, so they have not been used for a long time.

capacitive screens.

Design capacitive screens is quite complex, and it is based on the fact that the human body and the display together form a capacitor that conducts alternating current. Such screens are made in the form of a glass panel, which is covered with a resistive material so that electrical contact is not hindered. The electrodes are located at the four corners of the display and are supplied with an alternating voltage. If you touch the surface of the display, then there will be an alternating current leakage through the aforementioned "capacitor". This is recorded by sensors, after which the information is processed by the microprocessor of the device. Capacitive displays can withstand up to 200 million clicks, they have an average level of accuracy, but, alas, they are afraid of any influence of liquids.

Projective-capacitive screens.

Projection-capacitive screens can, unlike the previous types considered, be able to detect several clicks at once. On the inside there is always a special grid of electrodes, and during contact with them a capacitor will be formed. In this place, the electric capacitance will be changed. The controller will be able to determine the point at which the electrodes crossed. Then the calculations take place. If you immediately press the screen in several places, then not one capacitor will be formed, but several.

Screen with a grid of infrared rays.

The principle of operation of such displays is simple, and to some extent it is similar to the matrix. In this case, the conductors are replaced with special infrared rays. Around this screen there is a frame in which there are built-in emitters, as well as receivers. If you tap on the screen, then some beams will overlap and they cannot reach their own destination, namely the receiver. As a result, the controller calculates the contact point. Such screens can transmit light, they are durable, since there is no sensitive coating and mechanical touch does not occur at all. However, such displays currently do not meet high accuracy and are afraid of any contamination. But the diagonal of the frame of such a display can reach 150 inches.

Touch screens on surface-acoustic waves.

This display is always made in the form of a glass panel, in which piezoelectric transducers are embedded, located at different angles. There are also reflective, receiving sensors along the perimeter. The controller is responsible for generating signals whose frequency is high. After that, the signals are always sent to piezoelectric transducers, which can convert the received signals into acoustic vibrations, which are subsequently reflected from reflective sensors. The waves can then be picked up by receivers, resent to piezoelectric transducers, and then converted into an electrical signal. If you press the display, the energy of the acoustic waves will be partially absorbed. Receivers are receptive to such changes, and the processor can calculate touchpoints. The main advantage is that touch screens based on surface acoustic waves track the coordinates of the pressing point, the pressing force. Displays of this type are durable, because they can withstand 50 million touches. Most often they are used for slot machines, reference systems. It should be taken into account that the operation of such a display may be inaccurate in terms of ambient noise, vibration, acoustic pollution.

Today, no one is surprised by a touch screen phone. Manual control has become fashionable, but few people think about what happens when you touch the display. I'll cover how the most common types of touch screens work. The convenience and productivity of working with digital technology depends primarily on the information input devices used, with the help of which a person controls the equipment and downloads data. The most massive and versatile tool is the keyboard, which has now become widespread. However, it is not always convenient to use it. For example, the dimensions of mobile phones do not allow large keys to be installed, as a result of which the speed of entering information is reduced. This problem was solved by using touch screens. In just a few years, they revolutionized the market and began to take root everywhere - from mobile phones and e-books to monitors and printers.

The beginning of the sensory boom

Buying new smartphone, on the body of which there is not a single button or joystick, you hardly think about how you will control it. From the user's point of view, this is not difficult: just touch the icon on the screen with your finger, which will lead to the performance of some action - opening the input window phone number, SMS or address book. Meanwhile, 20 years ago, one could only dream of such opportunities.

The touch screen was invented in the USA in the second half of the 60s of the last century, but until the early 90s it was used mainly in medical and industrial equipment to replace traditional input devices, the use of which is fraught with difficulties under certain operating conditions. As the size of computers decreased and the appearance of PDAs, the question arose of improving their control systems. In 1998, the first handheld with a touch screen and an input and handwriting recognition system appeared. Apple Newton MessagePad, and soon communicators with touchscreens.

In 2006, almost all major manufacturers started producing smartphones with touch screens, and after the advent of Apple iPhone in 2007, a real touch boom began - displays of this type appeared in printers, e-books, various types of computers, etc. What happens when you touch the touch screen, and how does the device “know” exactly where you clicked?

How a Resistive Touch Screen Works

Over the 40-year history of touch screens, several types of these input devices have been developed, based on different physical principles that are used to determine the location of a touch. Currently, the most widely used two types of displays - resistive and capacitive. In addition, there are screens that can register several clicks at the same time ( Multitouch) or just one.

Screens made using resistive technology consist of two main parts - a flexible upper and a rigid lower layer. Various plastic or polyester films can be used as the first, and the second is made of glass. On the inner sides of both surfaces, layers of a flexible membrane and a resistive (having electrical resistance) material that conducts electric current are deposited. The space between them is filled with a dielectric.

Along the edges of each layer there are thin metal plates - electrodes. In the back layer with resistive material, they are located vertically, and in the front - horizontally. In the first case, a constant voltage is applied to them, and an electric current flows from one electrode to another. This results in a voltage drop proportional to the length of the screen section.

When you touch the touch screen, the front layer flexes and interacts with the back, which allows the controller to determine the voltage on it and calculate the coordinates with it. touch points horizontally (x-axis). To reduce the influence of the resistance of the front resistive layer, the electrodes located in it are grounded. Then the reverse operation is performed: voltage is applied to the electrodes of the front layer, and those located in the rear layer are grounded - this way it is possible to calculate the coordinate of the touch point along the vertical (Y axis). This is the principle of operation of a four-wire (named after the number of electrodes) resistive touch screen.

In addition to four-wire, there are also five- and eight-wire touch screens. The latter have a similar principle of operation, but higher positioning accuracy.

The principle of operation and design of five-wire resistive touch screens are somewhat different from those described above. The front resistive layer is replaced by a conductive layer and is used solely to read the voltage value on the rear resistive layer. Four electrodes are built into it at the corners of the screen, the fifth electrode is the output of the front conductive layer. Initially, all four electrodes of the back layer are energized, and on the front layer it is zero. As soon as such a touch screen is touched, the upper and lower layers are connected at a certain point, and the controller detects the change in voltage on the front layer. So he determines that the screen has been touched. Next, the two electrodes in the back layer are grounded, the coordinate of the touch point along the X axis is calculated, and then the other two electrodes are grounded, and the coordinate of the touch point along the Y axis is calculated.

Working principle of capacitive touch screen

The principle of operation of capacitive touch screens is based on the ability of the human body to conduct electric current, which indicates the presence of electrical capacitance. In the simplest case, such a screen consists of a solid glass substrate on which a layer of resistive material is deposited. Four electrodes are placed at its corners. From above, the resistive material is covered with a conductive film.

A small alternating voltage is applied to all four electrodes. At the moment a person touches the screen, an electric charge flows through the skin to the body, and an electric current occurs. Its value is proportional to the distance from the electrode (panel corner) to the touch point. The controller measures the current strength across all four electrodes and, based on these values, calculates the coordinates of the touch point.

The positioning accuracy of capacitive screens is almost the same as that of resistive ones. At the same time, they transmit more light (up to 90%) emitted by the display device. And the absence of elements subject to deformation makes them more reliable: the capacitive screen withstands more than 200 million clicks at one point and can operate at low temperatures (down to -15 ° C). However, the front conductive coating used for position determination is sensitive to moisture, mechanical damage, and conductive contaminants. capacitive screens are triggered only when they are touched with a conductive object (hand without a glove or a special stylus). Screens of this type made according to the classical technology are also not able to track several clicks at the same time.

The projected-capacitive touch screen, which is used in iPhones and similar devices. It has a more complex structure compared to conventional capacitive screens. Two layers of electrodes are deposited on a glass substrate, separated by a dielectric and forming a grating (the electrodes in the lower layer are located vertically, and in the upper layer - horizontally). The grid of electrodes together with the human body forms a capacitor. At the point where the finger is touched, its capacitance changes, the controller detects this change, determines at which intersection of the electrodes it occurred, and calculates the coordinate of the touch point from this data.

These screens also have a high transparency and are able to operate at even lower temperatures (down to -40 °C). Electrically conductive contaminants affect them to a lesser extent, they react to the gloved hand. High sensitivity makes it possible to use a thick layer of glass (up to 18 mm) to protect such screens.

Working principle of four-wire resistive touch screen

- The upper resistive layer bends and comes into contact with the lower one.

- The controller detects the voltage at the touch point on the bottom layer and calculates the X coordinate of the touch point.

- The controller detects the voltage at the touch point on the top layer and determines the Y coordinate of the touch point.

Working principle of five-wire resistive touch screen

- Touch the screen with any hard object.

- The upper conductive layer flexes and touches the lower one, indicating that the screen has been touched.

- Two of the four electrodes of the bottom layer are grounded, the controller determines the voltage at the touch point and calculates the X coordinate of the point.

- The other two electrodes are grounded, the controller determines the voltage at the touch point and calculates the Y coordinate of the point.

Advantages

- Low cost

- High resistance to dirt

- Can be touched by any hard object

Flaws

- Low durability (1M single-point clicks for 4-wire, 35M clicks for 5-wire) and vandal resistance

- Low light transmission (no more than 85%)

- Do not support multitouch

Device examples

- Phones (eg Nokia 5800, HTC Touch Diamond), PDAs, computers (eg MSI Wind Top AE1900), industrial and medical equipment.

Principle of operation

- The screen is touched with a conductive object (finger, special stylus).

- Current flows from the screen to the object.

- The controller measures the current strength at the corners of the screen and determines the coordinates of the touch point.

Advantages

- High durability (up to 200 million clicks), the ability to work at low temperatures (up to -15 ° C)

Flaws

- Susceptible to moisture, conductive dirt

- Do not support multitouch

Device examples

- Phones, touchpads (for example, in the iRiver VZO player), PDAs, ATMs, kiosks.

Principle of operation

- The screen is touched or a conductive object is brought close to it, forming a capacitor with it.

- At the point of contact, the electrical capacitance changes.

- The controller registers the change and determines at which intersection of the electrodes it occurred. Based on these data, the coordinates of the touch point are calculated.

Advantages

- High durability (up to 200 million clicks), the ability to work at low temperatures (down to -40 ° C)

- High vandal resistance (the screen can be covered with a layer of glass up to 18 mm thick)

- High light transmission (over 90%)

- Support Multitouch

Flaws

- React to the touch of only a conductive object (finger, special stylus)

Device examples

- Phones (for example, iPhone), touchpads, screens of laptops and computers (for example, HP TouchSmart tx2) electronic kiosks, ATMs, payment terminals.

Windows 7

In addition, it became possible to control the computer using the Scroll, Forward/Back, Rotate, and Zoom gestures. The Windows 7 operating system is much better adapted to work with touch displays than all previous versions. 06 this is evidenced by the modified interface and the taskbar, in which instead of rectangular buttons symbolizing running programs, appeared square icons- they are much more convenient to press with your finger. In addition, there appeared new feature- jump lists that allow you to quickly find recently opened files or frequently used items. To activate this feature, just drag the program icon to the desktop.

For the first time in operating system Windows added the option to recognize touch gestures, which are associated with the execution of certain functions. So, in Windows 7 touch scrolling appeared and the same as, for example, in the Apple iPhone, the ability to enlarge pictures or documents by moving two fingers in different directions. Not without movement, responsible for the rotation of the image. Operations such as copy, delete, and paste can also be assigned separate gestures. The on-screen keyboard buttons light up when touched, making it easy to use on a touch screen. And the ability to recognize handwriting allows you to quickly enter small messages.

Infrequently, we think about how the display of the device in our hands works. But sometimes there are times when a recently purchased phone or tablet refuses to respond to the usual digital pen from an old device. In this case, it becomes obvious that the new screen is assembled using some other technology. Here it is already remembered that there are resistive and capacitive screens, the latter of which are gradually replacing the former.

It is worth noting that few people know about the difference between surface and projected capacitive displays. But the screens of almost all modern tablets, smartphones with Android or iOS from Apple are projected capacitive, thanks to which such an already necessary function as multitouch is possible.

Surface capacitive screens

All capacitive screens use the fact that all objects with electrical capacitance, including the human body, conduct alternating current well.

The first copies of capacitive touchscreens operated on direct current, which simplified the design of electronics, the analog-to-digital converter in particular, but contamination of the screen or hands often led to failures. For direct current, even a negligible capacitance is an insurmountable obstacle.

Capacitive screens, like resistive screens, are assembled in the simplest case from LCD or AMOLED screen giving an image at the very bottom and a touch active panel on top .

The active part of surface-capacitive screens is a piece of glass coated on one side with a transparent, high-resistance material. Indium oxide or tin oxide is used as this electrically conductive substance.

Four electrodes are located at the corners of the screen, through which a small alternating voltage is applied, the same from all sides. When touching the screen surface with an electrically conductive object or directly with a finger, a current leaks through the human body. The flow of negligibly small currents is recorded simultaneously in all four corners by sensors, and the microprocessor determines the coordinates of the contact point by the difference in current values.

The surface capacitance shield is still fragile, since its conductive coating is applied to the outer surface and is not protected by anything. But not as gentle as resistive, since there is no thin soft membrane on its surface. The absence of a membrane improves the transparency of the display, and allows the use of a less bright and energy-saving backlight.

Projected capacitive screens

This type of touch screen is able to simultaneously determine the coordinates of two or more touch points, that is, it supports the multi-touch function. This type of display is installed on all modern mobile devices.

They work on a principle similar to surface-capacitive screens, the difference lies in the fact that they have an active conductive layer applied inside, and not on the outer surface. Thanks to this, the active panel is much more secure. You can cover it with glass up to 18 mm thick, thus making the touch screen extremely vandal-resistant.

When touching the touch screen, a small capacitance forms between the human finger and one of the electrodes behind the glass. The microcontroller probes with a pulsed current exactly where on the grid of electrodes the voltage has increased due to the sudden capacitance. The screen does not react to falling drops of water, since such conductive interference is easily suppressed by the software method.

A common disadvantage for all capacitive screens is the inability to work with them with any insulating objects. You can only use a special stylus or a bare finger. They will not react to a comfortable plastic pen or a hand in a warm glove.