Almost didn't exist. Currently, there are more than 50 types of one-dimensional (1D) barcodes and more than 70 two-dimensional (2D) ones. This means that to print a barcode using a label printer, you need to clearly define the purpose of its creation. To make the optimal choice, you need to understand what type and type of barcode is used for what, what are the advantages and disadvantages of a particular barcode and which ones are available for creation and printing.

So, which barcode should you choose to print? One-dimensional (1D) or two-dimensional barcode (2D), advantages and disadvantages:

1D barcode (one-dimensional)

A one-dimensional barcode is a pattern of lines of varying thickness, which is why it is called linear. A linear barcode encrypts information in only one dimension (usually horizontal). Only its length is scanned. Recognition of one-dimensional barcodes occurs quickly and with fewer errors.

Common one-dimensional barcodes:

EAN-13 and EAN-8;

UPC-A and UPC-E;

Code128;

Code39;

GS1 DataBar.

Advantages:

The versatility and prevalence of 1D barcodes.

To encode brief information about a product or service and automate trade turnover, the use of linear barcodes is quite rational and justified. The equipment for reading most popular one-dimensional barcodes is the most common.

Flaws:

Can only contain a maximum of 30 characters of information;

Contains only ASCII characters (American Standard Character Code Table characters and some special codes);

Relatively large linear barcode size (low space efficiency);

Severe damage to the barcode significantly reduces the likelihood of reading.

Thus, the use of one-dimensional barcodes can be recommended for trading enterprises of various sizes and areas, in production, for inventory and other areas.

2D (two-dimensional) barcode:

A two-dimensional code contains information in both horizontal and vertical dimensions. In general, most 2D barcodes are not exactly “bar” codes. This name was passed on to them from their “younger brothers” - one-dimensional linear codes.

2D barcode has several types of encoding method ( types of 2D barcode). The most popular three:

Linear invoice 2D barcode. Based on stacking multiple 1D barcodes vertically on top of each other, such as Code 16K, Code 49, PDF417;

Matrix 2D barcode. It is an overlay of black and white images inside the matrix, for example Aztec, Maxi Code, QR Code, Data Matrix;

Postal 2D barcode. The encoding consists of a combination of strips of different lengths. Most often used postal services. Examples: Postnet, BPO 4-State, Australian Post Code.

Commonly used two-dimensional codes include:

Data Matrix (usually for small electronic parts);

Maxi Code (created by the UPS delivery service for tracking and processing cargo and parcels);

Aztec (developed by Welch Allyn and can contain up to 3832 digits or 3067 characters or 1914 bytes of data);

QR Code (QR = Quick Response). Invented in Japan by Denso Wave in 1994. Holds up to 7089 digits or 4296 characters and produces even fewer reading errors than one-dimensional barcodes. QR codes now very popular, usually used to store information that contains consumer value - they contain data about a link to some web resource, address, or virtual business card, data about a ticket or electronic queue number. Many label printers have the ability to print QR- code;

Vericode, PDF417, Ultracode, Code 49, Code 16K and others.

Decoding of two-dimensional barcodes is carried out by special photo scanners (image scanners or imagers), raster scanners or through a camera, for example a smartphone with a pre-installed special software. Attention! Don't produce 2D barcodes unless the person they are intended for has the means to process it!

Areas of application of a two-dimensional barcode (using the example of a two-dimensional PDF417 barcode):

Transportation of goods

Typically, the delivery scheme for something expensive includes a supplier, a transport agent, a transport company, and the end client. Every time the cargo moves from one to another, documents and/or invoices are drawn up or filled out, which can contain a lot of information - about the cargo, the sender, the recipient, etc. If you take notes manually, you waste time and create errors.

With a 2D barcode, all of this information can be encoded. Entering a barcode into accompanying documents is not difficult, and you can apply it to the cargo by printing a sticker on a label printer. This solution increases work efficiency.

Identity cards

The PDF417 barcode was first used for personal identification by the US Army. It encoded information about name, rank, photo and other information. Such an ID is difficult to counterfeit, and the barcode remains readable even if damaged. Identity confirmation using such a card or other ID with a barcode can be used in any area.

Documents and reports

The Japanese insurance company "Seimei Insurance Company" was the first to use PDF417 to encrypt information about clients' personal files. At any time, you can bring a document with a two-dimensional barcode to the scanner and display the information on a computer screen with a database.

Inventory

Any company can encode information about any of its assets, print a label with a barcode on a label printer and stick it on the asset itself. In this way, inventory operations or asset tracking are greatly simplified. Most often, to automate inventory, it is more rational to use one-dimensional linear barcodes. Reading and checking information from labels affixed to assets occurs using a barcode scanner or data collection terminal.

Combine 1D and 2D barcodes

Sometimes it is useful to use 1D and 2D barcodes together. The first, for example, for the registration number, and the second for encoding all data. If one-dimensional and two-dimensional barcodes are combined - located side by side on one image, then such barcodes are called composite.

So, what type of barcode should you choose to print on a label printer? In principle, everything is simple here: if there is little information and a simpler decoding tool is used (LED or laser scanner), then produce one-dimensional barcodes. If there is a lot of information and you are sure that they will be able to decipher it, then, without a doubt, choose a two-dimensional code, for example a QR code, Datamatrix or PDF417.

Barcode is commonly used for fast and reliable data entry, improving productivity. Below is a list of the most common areas in which barcodes are used:

· Point of Sale (POS) is one of the most common areas in which barcodes are used to record goods sold.

· Inventory - barcodes are actively used in warehouses to account for goods. Portable scanners are used to monitor the shipment and receipt of goods. The data collected by the scanner can be downloaded periodically or in real time to a computer depending on the system you are using, allowing companies to reduce inventory levels and thereby reduce the cost of transportation costs.

· Shipping - Barcodes are used throughout the world by the transportation industry to label everything from letters to large shipments. The barcode encodes the sender, recipient, courier and other information.

· Identification - Employee ID cards with a printed barcode are used by various companies around the world.

· Time recording systems - barcodes are used to record the arrival and departure of workers, which allows you to get rid of paper schedules and timers and automatically calculate salaries.

· Packaging - barcodes are used to identify the lot number, serial number and delivery information. Labeling can be used to automatically sort out shipments, automate receipts, and increase control over the transportation of goods.

· Data collection - medical forms require a lot of time and patience to fill them out. By using barcodes, information can be quickly and easily entered into a computer database. By reducing the cost of data collection, you increase the quality of service.

From all of the above, we can conclude that barcoding is used not only in the trade sector, but also in various areas of human life.

> Encoding methods

Today, there are 2 ways to encode product information - linear and two-dimensional.

Linear method

Linear barcodes are those that are readable in one direction (horizontally). In such a code, a symbol is represented by a sequence of characters lined up in one line. Linear symbologies allow you to encode a small amount of information (up to 20-30 characters, usually numbers). The amount of information in a linear barcode does not affect the height of the barcode (and vice versa). With the same width of a linear barcode, its height can be different. However, the higher the barcode, the more likely it is to be read the first time.

There are linear barcodes different types:

EAN-13 EAN-8 UPC GS1-128

Codabar Code-39, etc.

EAN barcode

The most widely used code in international practice is EAN - European Article Numbering.

Depending on the area of application, there are 3 groups of EAN product codes:

1.) international, used both inside and outside the country;

2.) national, used within one country, mainly for retail trade in loose goods;

3.) local codes used only in the control systems of a specific enterprise.

The EAN barcode is a common “language” for all countries, with the help of which you can uniquely identify a product at any stage of its movement from the manufacturer to the buyer. The EAN code meets the following requirements:

has international significance;

does not depend on the requirements of individual users;

identifies any product globally using a unique code;

convenient in structure for computer reading;

suitable for collecting and exchanging information about goods, both within the country and in international trade; convenient for consumers when paying for purchased goods.

All versions of the EAN code have the following common characteristics:

the symbols have a general rectangular shape, formed by a sequence of dark parallel strokes and light spaces between them, perpendicular to an imaginary base line or reference straight line and have a light field on all sides;

light spaces and dark strokes consist of light and dark modules of the same length (later in the text, when describing EAN symbols, the dark module will be represented as “1” and the light module as “0”);

The vast majority of modern scanners recognize all standard linear barcodes, including codes such asUPC/EAN, Code 39, Code 128, Codabar, 2 of 5 Interleaved (ITF), which have been accepted as pan-European standards for almost 20 years, and other symbols created for use in narrow areas of activity. Two-dimensional codes, e.g. Aztec, DataMatrix, QR and others, in particular linear and stack ones, can only decode matrix photo scanners.

If you are involved in the retail trade - food, clothing, books and other consumer goods, most likely, a “regular” laser scanner will be enough for you, since you are dealing mainly with symbols ISSN , which is technologically the same) and D codes even if you are currently using 1 D and you are happy with everything. More on this a little later.

So, if you purchased scanners (LED or laser) to read linear symbols, then to read 2 D codes, you will need to separately purchase matrix photo scanners. Naturally, the question arises of what to do with the “old” ones, since their functions successfully overlap the “new” ones. In addition, photo scanners tend to be more expensive.

If on this moment you need to read only linear barcodes, and in the future, perhaps (or not), also two-dimensional with stacked ones, but you are confused by the two above arguments and you are looking for a compromise solution, we suggest you think about it together. Let's start with brief educational program. So…

What types of barcodes are there?

There are two types of bar codes:two-dimensional (2D).

Linear codes (picture below) are a sequence of parallel black and white stripes of varying widths. Dark stripes are called strokes, and light stripes are called spaces. Information is carried by a strictly specified standardized width of strokes and spaces, as well as their location relative to each other.

Since such a code is read only in the horizontal direction, the “elongation” of the code is explained solely by the ease of reading from the point of view of aiming and recognizing damaged symbols. This property of code is also called "vertical redundancy".

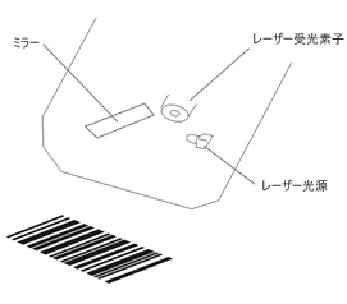

You constantly come across such codes in Everyday life. The most common linear codes are EAN, UPC, Code 128, Interleaved 2 of 5 and code family GS 1 DataBar (ex - ESS ). You can see the process of reading such a code with the simplest single-beam laser scanner in the picture to the right of this text.

The two-dimensional code contains information both horizontally and vertically. In fact, any printed text is an analogue of a two-dimensional code. Since both directions contain information, the possibility of using vertical redundancy is lost. Here b Dealing with errors is ensured quite simply -Most two-dimensional codes use special checksums to ensure the accuracy of the entered information.

The two-dimensional code contains information both horizontally and vertically. In fact, any printed text is an analogue of a two-dimensional code. Since both directions contain information, the possibility of using vertical redundancy is lost. Here b Dealing with errors is ensured quite simply -Most two-dimensional codes use special checksums to ensure the accuracy of the entered information.

High speed decoding of two-dimensional barcodes is achieved using photo scanners that have a camera and special decoding software.

Initially 2D codes were designed for applications that do not provide sufficient space to accommodate a conventional barcode identifier. The first use for such symbols was packaging medicines in healthcare. These packages are small in size and have little space to accommodate a barcode. The electronics industry is also showing interest in high-density and 2D codes due to the reduction in feature and product sizes.

More recently, the ability to encode a portable database has made 2D symbologies attractive for applications where minimizing code size is not a primary requirement. For example, storing name, address and other information on cards. If a card contains only an identifier that serves as a key to a database, then it is likely that several cards will have to be checked against a huge database containing millions of names. This will require large expenses for computer processing and storage of such a database. If all important information will be printed simultaneously with the printing of the offer on the card, That there will be no increase in costs, and the information will be quickly entered from the card into the computer.

Today, more than 20 different 2D barcode symbologies have been developed. The most popular are Aztec, Data Matrix, QR Code and MaxiCode . All of them are actively used in manufacturing, logistics, warehouse accounting, pharmaceuticals and healthcare, banking sector, public utilities, etc.

Barcodes are read using special devices - barcode readers. They can be scanners, data collection terminals, and even mobile phones with special software installed (but with low performance).

The principle of operation of the readers is to convert the encoded graphic information, presented as a sequence of contrasting stripes or squares, into an alphanumeric one.

Above right is an example. Aztec code with a coded message. You can count it with mobile phone and compare the amount of encoded information with the linear code in the same section. In both cases it is the phrase “ Hello, world !”. If you wish, you can read W. Blake’s poem “ tiger ”, encoded in QR -code. The originality of the execution is solely intended to show the possibility of self-correction and readability even in such a low-contrast and “cloudy” design.

Why 2D?

Despite the fact that linear barcodes continue to be used in industry, trade, logistics, document management and healthcare, two-dimensional symbols are becoming increasingly popular. This is justified by the following factors.

Firstly, this is the volume and type of encrypted information. Linear symbologies can hold about 30 characters (depending on the specific code), while two-dimensional symbologies can store about 1.5 pages A 4 texts. 2D symbols are gradually becoming the standard for such areas of human activity as healthcare and industrial production (especially small and unique parts, as well as microcircuits).

A barcode can be used as an identifier (a key to a database) and as an information carrier (the database itself).

In the first case, it is necessary to encode a small amount of information, which is presented in the form of a linear code. An example of this universal code can serve Code 39, capable of encrypting numbers and lowercase Latin letters and its extended version Code 128, with the ability to encode data format ASCII.

In the second case, a two-dimensional barcode should be used. The most common standard is the code PDF 417 (quasi-2 D ), since its use does not require licensing, it is widespread, and, therefore, the equipment for its recognition is also capacious (the ability to encode approximately 2500 characters).

The next article talks about

Let's first define what this might look like.

Increasingly, on products we are seeing the appearance of large squares with various fillings of black dots.

This is a new variety barcode to encrypt the necessary information.

This modification was developed by the Japanese company Denso-Wave.

Target 2 D code or QR code - Like any barcode, it makes it easier to work with the product.

Can you imagine if, when receiving goods, the storekeeper manually entered all the information - production date, country of manufacturer, recipient, composition, etc. Receiving one unit of goods would take up most of his working time.

And so it takes 0.5 seconds - it reads the code with a special barcode scanner and receives all the information in its database.

Why 2D code?

Ordinary barcode has "vertical redundancy", meaning that the same information is repeated vertically. This is truly a one-dimensional barcode. the height of the strokes can be reduced without losing information. However, vertical redundancy allows a barcode that has printing defects (such as spots or gaps) to remain readable.

A two-dimensional 2d code contains information both horizontally and vertically. In fact, all alphabets are an analogue of a two-dimensional code. Since both directions contain information, the possibility of using vertical redundancy is lost. To prevent loss of readability and ensure fast reading, another technology must be used. The fight against errors is ensured quite simply - most two-dimensional codes use special checksums to guarantee the reliability of the entered information.

And with the introduction of 2With QR codes, it has become possible to encrypt even more information while taking up minimal space.

2D codes were originally developed for applications that did not provide enough space to accommodate a conventional barcode identifier. The first application for such symbols was the packaging of medicines in healthcare. These packages are small in size and have little space to accommodate a barcode. The electronics industry is also showing interest in high-density and 2D codes due to the reduction in feature and product sizes.

PDF 417

PDF417 stack symbology was introduced in 1991. PDF comes from the abbreviation Portable Data File, a barcode symbol consisting of 17 modules, each containing 4 bars and spaces (hence the number 417). The barcode is open for public use.

The code structure supports encoding a maximum number of 1000 to 2000 characters in a single code, with an information density of 100 to 340 characters. Each code contains a start and stop group of bars that increase the height of the barcode.

The PDF417 code is read using a special laser or CCD scanner. To print the code, you should use printers with good resolution(thermal transfer or laser).

Aztec Code

Aztec Code was introduced by Andy Longacre of Welch Allyn Inc. in 1995 and open to general use. Aztec Code is designed to be easy to type and easy to decipher. The barcode is a square matrix with concentric squares in the center, which serve to determine the position of the code relative to the scanner, and a measuring ruler along the edge of the code. The smallest Aztec barcode has an area of 15x15 modules, the largest - 151x151. Minimum code Aztec encodes 13 digits or 12 letters, and the maximum is 3832 digits or 3067 letters or 1914 bytes of data. Symbolism does not require a free zone around the barcode. There are 32 gradations of code size with the ability to customize error protection using the Reed-Solomon method from 5% to 95% of the code area. The recommended level is 23% of the code capacity plus 3 code words.

All 8-bit values are encoded. Values 0 - 127 are represented as the ASCII character set, values 128-255 are represented as ISO 8859-1, Latin Alphabet No.1. In addition to data, two service characters can be encoded: FNC1 for compatibility with some existing applications and ECI (escape sequence) for standardized message encoding.

Data Matrix QR codes

Data Matrix code from CiMatrix is a two-dimensional code designed to fit a large amount of information into a limited surface area. A Data Matrix barcode can store from one to 500 characters. The code can scale from 1-mil density to 14-inch area. This means that Data Matrix code has a theoretical maximum density of 500 million characters per inch! In practice, density is, of course, limited by the resolution of printing devices and scanners.

The code has several other interesting features. Since information is encoded by the absolute position of the element within the code, i.e. position relative to the boundaries of the code, the code is not as sensitive to printing defects as a traditional barcode. The coding scheme has high level redundancy, data is dispersed within the barcode symbol. This allows you to maintain code readability even if it is partially damaged or part of the code is lost. Each code has measuring rulers, which you see as a solid line along one edge of the symbol and evenly spaced square dots of the same size along the other edge. These rulers are used to determine the orientation and density of the code.

There are two main character sets. They use the folded error correction encoding that was used in the first versions of the Datamatrix code, these versions are described as ECC-000...ECC-140. The second set is described as ECC-200 and uses the Reed-Solomon error correction method. Symbols ECC-000 .. 140 always have an odd number of modules on each side of the square. ECC-200 symbols always contain an even number of elements on each side. The maximum ECC-200 character capacity is 3116 digits or 2335 letters in a 144-unit character.

The most popular applications for Datamatrix are marking small items such as electronic components and printed circuit boards electronic devices. These applications take advantage of Datamatrix's ability to fit approximately 50 characters into a 3mm code and the fact that the code can be read at 20 percent print contrast.

The code is read by a CCD camera or CCD scanner. Characters ranging from 1/8" to 7" in area can be read from a contact distance of up to 36 inches. The normal reading speed is 5 codes per second.

Comparative comparative characteristics 2d code with other information encryption options.

|

Technology characteristics |

RFID |

Barcode |

Data Matrix |

|

The need for direct visibility of the tag |

Read even hidden marks |

Reading without line of sight is impossible |

|

|

Memory |

From 10 to 10,000 bytes |

Up to 100 bytes |

Up to 2048 bytes |

|

Ability to rewrite data and reuse tags |

Eat |

No |

No |

|

Registration range |

Up to 100 m |

Up to 12 m (depending on barcode size) |

No data |

|

Simultaneous identification of multiple objects |

Up to 200 marks per second |

Impossible |

Depends on the reader |

|

Resistance to environmental influences: mechanical, temperature, chemical, moisture |

Increased strength and resistance |

Depends on the material it is applied to |

|

|

Tag lifetime |

More than 10 years |

Up to 20 years or more (depending on the material to which it is applied) |

|

|

Possibility of creating a fake |

Impossible |

Easy to fake |

It is possible to fake |

|

Work when the tag is damaged |

Impossible |

Difficult |

Possible |

|

Moving Object Identification |

Yes |

Difficult |

Possible |

|

Resistance to interference in the form of electromagnetic fields |

Very weak |

Eat |

Eat |

|

Identification of metal objects |

Possible |

Possible |

Possible |

|

Use of both stationary and hand-held terminals for identification |

Yes |

Yes |

Yes |

|

Possibility of introduction into the human or animal body |

Yes |

Difficult |

Difficult |

|

Dimensions |

Medium and small |

Small |

Small and ultra-small |

|

Price |

Comparison of 2d codes.

Alexey Maksimov

We are all almost accustomed to stationary or compact hand-held terminals, with the help of which sellers of self-service stores deftly read striped barcodes applied to goods. As a rule, this procedure speeds up the purchase process and facilitates computer accounting of the movement of goods.

The role of the barcode cannot be overestimated. After all, a label with strokes contains basic information - a link to a position in a computer database that stores all information about the product (name, manufacturer, price, etc.). Portable terminals for reading these codes are quite widely represented on the Russian market (see, for example, PC Week/RE, No. 10/98, p. 29), so retailers really have a choice.

2D Barcode Samples

But technology does not stand still; one-dimensional barcodes and devices for applying and reading them are being replaced by two-dimensional barcodes and related equipment. At the CeBIT’98 exhibition, my attention was drawn to the new compact universal scanner QHT-1000 of the Japanese corporation Denso, part of the Toyota Tsusho concern. This device can read and decode both 1D bar code (UPC, EAN, ITF, NW7, Code 39 and Code 128) and 2D Quick Response Code (QR Code) specifications developed by Denso. But before I talk about the capabilities of this scanner, I’ll try to briefly explain what a two-dimensional barcode is.

A little bit of history

The history of 2D barcodes has developed in two directions. The first - the creation of matrix codes - was born in the early 80s with the appearance of two developments: Vericode from the American company Veritec and CP Code from the Japanese company ID Tech. In the late 80s, International Data Matrix and United Parcel Services (UPS), respectively, introduced their Data Matrix and Maxi Codes. In 1990, the Canadian company Array Tech Systems proposed an original version of the Array Tag matrix code, in which data was represented by hexagonal and octagonal shapes. A little later - in 1991 - the matrix code Code One of the American company Laserlight Systems appeared. The Denso company offered its QR Code in 1994, but it was followed - in 1995 - by the development of the Aztech Code by the American company Wellch Allyn.

The second direction - the creation of quasi-two-dimensional composite barcodes - began in 1985 with the advent of Code 49 of the American company Intermec, in which up to 8 rows of barcodes can be arranged in the same space occupied by a linear code. At the end of the 80s, several more developments were released: Codablock from the German company Identicode System, Code 16K from Laserlight Systems and PDF417 (PDF, Portable Data File) from Symbol Technologies (USA). And finally, in 1996, the American company Zebra introduced the Ultracode compound code, which claims to be universal.

Of all these codes, PDF417 deserves special attention. It is used by the US Army and other American government services. For example, it is applied to personal identification cards of personnel. As far as I know, several years ago the Russian Ministry of Defense began testing this code to see if it could be used for personal identification and military logistics. Unfortunately, I do not have data on the results of this project.

Another important feature of the PDF417 code is the Reed-Solomon error correction method built into it for the first time. This method was originally developed by mathematicians Reed and Solomon from Hughes Aerospace for Voyager-type space probes and was intended to improve the stability of reception and recognition of weak and noisy radio signals. In the case of a two-dimensional barcode, the method ensures that the image is read and decoded, even if a significant part of it is damaged (for example, torn off or crossed out)

Features of 2D Barcodes

In the case of a conventional (one-dimensional) barcode, information written using a combination of strokes and spaces of different widths is read linearly, in a direction orthogonal to the strokes (the length of the stroke does not carry any information load). This implies a limitation on the amount of information - usually it does not exceed several dozen characters. The main difference between a two-dimensional code is that it uses both orthogonal directions on the plane - vertical and horizontal - to store information. As a result, in terms of the volume of stored information, the capacity of a two-dimensional code can be hundreds of times greater than the capacity of a one-dimensional one. If a computer database is required when working with one-dimensional code, then in many cases the use of two-dimensional code allows one to abandon such a database, since the code capacity is sufficient to store complete information about the object. This is the qualitative difference between the two technologies.

Scanner Denso QHT-1000

I note that two-dimensional codes turn out to be indispensable, for example, in autonomous systems identification or, if necessary, storage of complex characters in languages such as Japanese or Chinese. Almost everything modern technologies two-dimensional codes, unlike one-dimensional ones, contain error correction tools and, therefore, guarantee greater reliability of data protection.

However, we must not forget about the cost. Devices for creating, applying, scanning and decoding 2D bar codes are much more complex and therefore more expensive than the commonly used linear code equipment. In fact, in terms of supported data volumes and functionality 2D coding technology occupies an intermediate position between 1D barcode and remote identification technologies.

As we have already said, two-dimensional codes are divided into composite and matrix. A composite code is a sequence of linear codes, which can be placed on the same area as a one-dimensional code by reducing the length of the strokes. The simplicity of the forms inherent in this code (rectangles of bars and spaces) allows it to be read using relatively simple laser scanners or linear readers. The matrix code is a partially filled black grid of (in most cases) square modules - data cells. Such a code is no longer read by a linear reader, but by a special area reader.

QR Code - bet on speed

When developing Denso's 2D matrix barcode, special attention was paid to reading/decoding speed. Company representatives claim that they managed to achieve an order of magnitude more high performance- 30 labels per second (each with a capacity of 100 characters) versus a maximum of 3 labels per second (of the same capacity) in Data Matrix or PDF417 encoding. The secret lies in the use of a combined method: reading occurs in all directions at once, and special position detectors (nested squares located in three corners of the label) help speed up the decoding procedure. Thanks to these icons, the scanner can easily and quickly understand both the size of the code and the orientation of the label on the plane.

The QR Code specification is in a state of development, but the main characteristics of the code can be judged by, for example, the QR Code Model 2 option. This option allows the following maximum code capacity (depending on the data type): 7089 digits, 4296 alphanumeric characters, 2953 binary characters (8-bit) or 1817 Japanese characters in Kanji-Kana encoding. It is possible to encode a mixture of data of different types. Data in a QR Code is represented by a collection of black and white dots, each of which is interpreted as a data unit, or module. The code size varies from 21x21 to 177x177 modules (increase increment is a multiple of 4). It is not difficult to estimate how much area is required for the label of a particular container. For example, if the code is 105x105 modules, and the size of each module is 0.25 square meters. mm, then the area of the code area will be 105x0.25 square meters. mm = 26.25 sq. mm. Here you need to add the necessary fields (at least four modules wide). As a result, we find that the required label area will be (105 + 8) x 0.25 square meters. mm = 28.25 sq. mm.

The Reed-Solomon error correction method used in QR Code involves adding a special code with coding logic to the recorded data. Depending on the required level of reliability, four levels of correction are used (naturally, for higher reliability you have to pay by increasing the volume of the summary code). These levels, designated L, M, Q and H, guarantee data recovery if the damaged label surface area does not exceed 7, 15, 25 and 30%, respectively.

Not all features of the QR Code are given here, but in this article we do not aim to give an exhaustive description of it; those interested in this topic can find more detailed information See specialized literature or the Denso Web site (www.denso.co.jp).

Universal scanner QHT-1000

Create code and not create it Hardware to work with him would be tantamount to the death of an interesting idea. That's why Denso offers various means applying and reading QR Code. If a wide range of label printers can be used for printing, then specialized scanners are required that use algorithms for quickly reading and decoding this particular code. Until recently, Denso produced the QS-10H handheld scanner, the QS-10P spot scanner and the QD-10 decoder camera. New in this series is the QHT-1000 handheld scanner, which recognizes both QR Code and basic linear codes.

This compact device weighing 320 g is equipped with 2 or 4 MB of memory, a backlit LCD screen with a resolution of 128x64 pixels, infrared IrDA-compatible and serial interfaces that provide wireless and wired data exchange with a PC. The QHT-1000 uses a 16-bit CMOS microprocessor and a 32-bit RISC processor, as well as a 0.25mm resolution CCD scanner. The size of the scanning area is 38x28 mm.

You can develop applications for the QHT-1000 using proprietary tools BHT-Basic 3.0. For this device, an infrared exchange utility, Ir-Transfer Utility, has been created that runs on the host computer, as well as Easy Pack Q software, designed to collect data presented in the form of QR Code and linear barcodes.

Conclusion

2D code technologies have been used for several years by large international companies and government agencies in many countries, using their main advantages - high capacity, autonomy, compactness, security and openness of standards. It’s probably impossible to list all possible areas of application. First of all, these are logistics, industrial production, Maintenance, medicine and various systems security in which it is necessary to identify individuals or control access rights. QR Code technology, for example, has been implemented at car factories of the Toyota concern, the parent company of Denso.

The author of this article can be contacted at: [email protected].