Or a smartphone, a person reads a lot of reviews and reviews, while he simply gets lost in the abundance of new and incomprehensible terms. For example, such a user may have a question: resistive screen - what is it? There is no need to prove that the main part of a tablet is the display. That is why it is worth understanding such a difficult concept.

Capacitive touchscreen or resistive touchscreen? This is a question that retailers and restaurant operators should ask themselves when evaluating sales technology. Understanding the advantages and disadvantages of each option will make the decision easier, so let's look at both.

Capacitive touch screens. A capacitive touchscreen consists of two layers of glass coated with a conductive agent such as iridium tin oxide. The conductor responds to the touch of a person's finger or a special tip on the screen. This causes the local electrostatic field to change and tells the system which area, number or icon on the screen has been affected. The capacitive touchscreen also supports multi-touch, such as pressing an icon and zooming in on the screen at the same time. The voltage is higher. The capacitive touch screen can be seen more easily. Makes it easier to enter more accurately. Because there is little or no opportunity for a capacitive touch system to interpret input inaccurately, the potential for errors—whether in a transaction or customer order detail—is minimized. Increased durability. A capacitive touchscreen can, in some ways, be more durable than its resistive counterpart. Frequently used areas on a capacitive touchscreen typically do not begin to deteriorate and become unresponsive over time and with heavy use. Additionally, the capacitive touch screen will continue to work and will become scratched, punctured, or cracked. This can happen if employees try to use the device with something other than a finger or stylus, if they press too hard on the glass, or if mobile device discarded. This is not the case with a resistive touch screen, which in most cases stops working whenever the surface is damaged. Offers easy and flexible work. . Because the capacitive touchscreen works even if it is damaged, there is no need to interrupt store or restaurant operations to install a replacement.

- What is this?

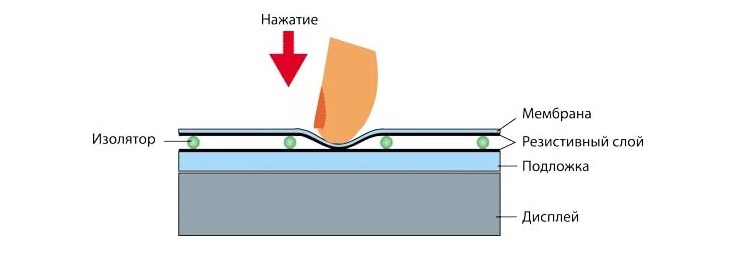

This term hides a display that is produced using the technology of the same name. Thanks to this, it is possible to ensure its special properties in comparison with the second common type - a capacitive screen. It is worth understanding in more detail what this technology is, as well as what it means for a specific user. To simplify, in general terms, thanks to such features, it is possible to turn a stylus or nail into something like computer mouse. The sensor includes two layers: glass and a special plastic membrane. An insulator layer is located between them. The deflection of the membrane to the glass, that is, the contact of these two layers, leads to a change in the level of resistance, which is recorded by the device itself, due to which the point of impact of the stylus is determined.

This minimizes customer disappointment and lost sales. Capacitive touch screen is increasingly becoming best choice among manufacturers of equipment for sale. Therefore, choosing where to sell capacitive touchscreen equipment will allow for a smooth transition to future improvements and ensure compatibility with new equipment. Is the future. . Advantages of resistive touch screen.

A resistive touchscreen consists of two flexible layers of material with a layer of air between them. It registers input when a small amount of pressure is applied to the top layer, enough to make contact with the bottom layer. Because the two layers of material used in a resistive touchscreen are synthetic rather than glass, its surface is more susceptible to scratches or wear than the surface of a capacitive touchscreen. Chalked it up to the more complex technological structure of the latter. Reacts to several types of touches. A resistive touchscreen will register input from gloved or unglazed fingers because they do not require touching with a special stylus or bare fingers like capacitive touchscreens. A resistive touchscreen can also register input from a thin contact point as it offers more sensors per inch than a capacitive touchscreen. It is less touch sensitive than a capacitive touchscreen. Ultra-sensitive touch sensitivity can be a good feature for a touchscreen. However, this is not always an advantage in environments where stray stimuli, such as spills and splashes, can cause the terminal to respond unintentionally.

- Most widely accepted.

- He has more low price than its capacitive touch screen.

If we consider what a resistive screen is, then it is worth determining how all this is expressed in practice, since in theory it may seem very strange. That is why it is worth considering the features of such technology in comparison with capacitive technology in order to understand what its advantages and disadvantages are. Among the primary advantages of such screens is their low cost. This technology is quite simple and well-tested, thanks to which it is possible to create quite budget models of phones, tablets and e-readers based on it. This device is very reliable, since the glass used is quite strong. If the gadget is equipped with a new generation sensor - a five-wire screen, then it will be especially reliable, since it is not afraid of even single breaks or cuts in the outer membrane.

If we consider what a resistive screen is, then it is worth determining how all this is expressed in practice, since in theory it may seem very strange. That is why it is worth considering the features of such technology in comparison with capacitive technology in order to understand what its advantages and disadvantages are. Among the primary advantages of such screens is their low cost. This technology is quite simple and well-tested, thanks to which it is possible to create quite budget models of phones, tablets and e-readers based on it. This device is very reliable, since the glass used is quite strong. If the gadget is equipped with a new generation sensor - a five-wire screen, then it will be especially reliable, since it is not afraid of even single breaks or cuts in the outer membrane.

Indeed, their use depends on your business environment and how you plan to use your touch devices. By using the information we provide, you will better understand these benefits and be sure to make the right choice for your unique business.

Brilliant engineers have developed various ways, with the help of which the user will talk to the machine. Today, however, we'll talk about one method - the touchpad. Surface capacitive protozoa: there is a thin layer of electrodes that lies under the surface of the glass, covered with a protective layer. Four electrodes at the corner of the panel provide electrical voltage to the film. When a conductive material is near the electrode film, a change in electrostatic capacitance occurs.

If we consider the resistive screen type, it is worth noting that it also has certain disadvantages. It is generally accepted that devices using such screens transmit less contrast and brighter images. Such devices do not allow multi-touch, that is, the use of some complex movements, for example, spreading your fingers to zoom in - a resistive screen will not allow this.

By measuring these changes, the controller determines where the touch occurred. Surface capacitance is often used on large surfaces because the sensory perception is not very accurate. It's a little more complicated. Under the glass and protective cover lies a diagram of the layers of electrodes. Pattern formation results in more accurate touch perception, which is why this type of touch panels is used on mobile phones and similar small devices. No force required: touch Touchpad reacts as soon as you place your finger about a millimeter away from the screen. Good quality Pictures: No matter indoors or in the sun, the picture quality is usually better than resistive screen. Touch bonding doesn't work with all materials: gloves, for example, aren't conductive, so you always have to press something conductive onto the screen to make contact. There are many workarounds for this, but it certainly poses a problem. Hygiene: Because a full finger connection is required, these types of screens are typically more colored and germ-filled than capacitive ones.

- Accurate touch recognition, especially with a projected capacitive screen.

- Multi-touch can be implemented.

- Price: Capacitive screens are usually a little more expensive than resistive screens.

What this is, you understand in general terms. Now it should be said that the user who chooses this or that gadget already has a good idea of what exactly he needs, because he can touch the screen with his hands, and here he does not need to master any abstract concepts such as processor power or version of the operating system.

Want to kindly move away like a maastro piano, capacitive is the display for you. Luckily, we now support them all, so you can choose which interface suits you best! You may have wondered what the difference is between a resistive and capacitive touch screen. And you may be asking which one is best for your situation. Chances are you've experienced resistive and capacitive technologies, but you may not have known what they were called or considered the technological implications for them.

Capacitive touch screens

Again, you can know all about capacitive and resistive touchscreens and the advantages and disadvantages of each. If you do this, perhaps you will be able to speak. However, if you find that your knowledge of resistive or capacitive technologies is somewhat wanting, read on and hopefully you'll learn a thing or two today.

It is important to note that we should not dismiss this type devices only because their price is lower. IN in this case cheaper does not mean worse, it just means that you won’t have to overpay for features that you personally don’t need. Now you understand what a resistive screen means.

Many people think that the era of touch screens began in the 2000s, with the release of the first PDAs (I hope there are no people who think that the first touch screen appeared in the iPhone?) However, this is not so - the first consumer device with touch display became... TV in 1982. A year later, HP's first touch PC appeared. 10 years later, in 1993, the Apple Newton appeared - the founder of the PDA, which introduced the fashion for styluses (although this was rather a necessity - the screen was resistive), and already in 2007, with the release of the iPhone, a modern capacitive screen appeared in the form which we are all accustomed to seeing. So the history of touch screens goes back 35 years, and quite a lot has happened in that time.

Resistive touch screen technology

Let's make sure we're starting off on the right foot here so we all understand the underlying technology of resistive and capacitive touchscreens. Resistive touchscreens rely on pressure from your fingertip or any other object to register input. They consist of two flexible layers with an air gap between them. In order for the touchscreen to register the input, you must press down on the top layer using a small amount of pressure to push the top layer down enough to make contact with the bottom layer.

Already from the name it is clear that such displays are based on electrical resistance. The design of such a screen is simple: there is a substrate above the display (so as not to deform it when pressed hard), after which there is one resistive layer, an insulator and a second resistive layer already on the membrane:

Voltage is applied to the left and right edges of the membrane and the lower and upper edges of the resistive layer on the substrate. What happens when we click on such a display? The resistive layers close, the resistance changes, and therefore the voltage also changes - and this is easy to register, after which, knowing the resistance of a unit of the resistive layer, you can easily find out the resistance on both axes up to the point of pressing, and therefore calculate the pressing point itself:

The technology behind capacitive touchscreens

The touch screen will then register exact location touch. Instead of relying on pressure, capacitive touchscreens instead sense conductance to register input—usually from the skin at the tip of a finger. Because you don't have to apply pressure, capacitive touchscreens are more sensitive than resistive touchscreens. However, because they work by measuring conductivity, capacitive touchscreens can only be used with objects that have conductive properties, including the fingertip, and special styluses designed with a conductive tip.

This is the operating principle of a four-wire resistive screen, and these are no longer used for one simple reason: the slightest damage to the membrane with a resistive layer leads to the screen no longer working correctly. And taking into account the fact that such a screen is usually poked with a sharp stylus, it is not at all difficult to cause damage.

Currently, resistive touch screens are more common in the rugged hand-held industry, while capacitive touch screens are more common among consumer devices such as Cell Phones. Resistive touchscreens have historically been a popular choice for rugged pocket makers for a number of reasons. However, capacitive technology is looking more attractive in recent times due to the many benefits it offers.

Benefits of resistive touch screens

For a quick comparison, here are a few benefits of each type of technology. Stylus Versatility: Because resistive technology is pressure-based, you can use anything for the stylus; you don't need a special stylus with a capacitive tip.

Then they decided to do it differently: the membrane became conductive, and all 4 electrodes were now located on the resistive layer of the substrate, but in the corners, and the voltage was supplied only to the membrane - that is, the screen became five-wire. What happens when you press it? The membrane touches the resistive layer, a current begins to flow, which is removed from 4 electrodes, which again allows, knowing the resistance of the resistive layer, to determine the point of contact:

More a high resolution Sensor: Resistive touchscreens have more sensors per square inch, so a thinner tip will work better on resistive touchscreens than capacitive touchscreens. This is important when the application buttons are quite small, making a thin tip more desirable.

Fewer accidental touches will be registered: In many cases, a capacitive touch screen is preferred over a resistive screen for greater responsiveness and sensitivity, there are cases where this greater sensitivity may not be desirable. Resistive touchscreens may be preferable when inadvertent touching of the screen is expected, such as when liquids may be present on the touchscreen, since a resistive screen will not sense light touches from liquids.

This type is already more “vandal-resistant” - even if the membrane is cut, the screen will continue to function normally (except, of course, at the place of the cut). But, alas, this does not cancel other problems that are common to all resistive screens, and there are many of them.

Firstly, such a screen only perceives one touch: it’s easy to guess that when you press with two fingers at once, the screen will think that you pressed in the middle of the line connecting the touch points. The second problem is that you really need to press on the screen, preferably with a sharp object (nail, stylus). Of course, you can get used to this, but this often led to characteristic scratches, which did not add beauty to the screen. The third problem is that such a screen transmits no more than 85% of the light flux, and due to its thickness there is no feeling that you are directly touching the image with your finger.

But, nevertheless, it also has advantages: firstly, it is very, very difficult to break the display in such a screen - it has “triple protection” in the form of a membrane, insulators and a substrate. The second plus is that the screen doesn’t care what you poke at it - you can work with it even with regular gloves (which is very important in winter). But, alas, these advantages did not outweigh the disadvantages, and with the release of the iPhone, a boom in capacitive screens began.

Surface capacitive screens

This, one might say, is a transitional type between the ones we are used to capacitive screens(which are projection) and the old resistive ones. The principle of operation here is similar to a five-wire screen: there is a glass plate covered with a resistive layer, and 4 electrodes in the corners, which supply a small AC voltage(I’ll explain why it’s not permanent a little lower). When we press on such a screen with a conductive grounded object, we get a current leak at the point of pressing, which can be easily registered:

Here is the answer to why the voltage is alternating - with a constant voltage there may be interruptions in operation if the grounding is poor, but with an alternating voltage this is not the case.

They also have a lot of problems: the screen is now less protected, and if the glass plate is damaged, the entire screen stops working. Again, multi-touch is not supported, and moreover, now the screen does not respond to a gloved hand or styluses - they basically do not conduct current.

The only advantage of such a screen is that it has become thinner and more transparent than a resistive one, but in general, few people appreciated this. But everything changed with the release of the iPhone, which used a slightly different type of touch screen that already supported multi-touch.

Projected capacitive screens

Now we have already come to modern type touch screens. According to the principle of operation, it differs significantly from the previous ones - here the electrodes are located in a grid on the inside of the screen (rather than 4 electrodes in the corners), and when you press the screen, your finger forms capacitors with the electrodes, by the capacitance of which you can determine the location of the press:

With such a screen device, you can press on it with several fingers at once - if they are located far enough (further than two adjacent electrodes in the grid), then such presses will be detected as different - this is how multi-touch appeared, first on 2 fingers in the iPhone, and Now it’s already 10 fingers in tablets. Large quantity There is no longer any need for clicks (there are not enough people with more than 10 fingers), and detecting more than 5-7 clicks at the same time places a serious load on the touch controller.

One of the advantages of such a screen, in addition to multi-touch support, is the ability to make OGS (One Glass Solution): protective glass screen with an integrated grid of electrodes and the display are one whole: in this case, the thickness is the smallest, and it seems that you are touching the image with your fingers. This also leads to the problem of fragility: when a crack appears on the glass, the grid of electrodes is guaranteed to break, and the screen stops responding to pressure.

These are the main types of touch screens, but there are many others. Let's start with, perhaps, the oldest type, with which touch screens began.

Infrared screens

Again, the principle of operation is clear from the name: at the edges of the screen there are many light emitters and receivers in the IR range. When pressed, the finger blocks part of the light, which allows you to determine the location of the press. The advantages of such screens at the dawn of their appearance were that they could be equipped with any display, which was done with a TV in 1982. The disadvantages are also obvious - the thickness of such a design turns out to be impressive, and the positioning accuracy is quite low.

Strain gauge screens

Screens that respond to pressure (strong pressure). Their huge advantage is that they are as “vandal-proof” as possible, which is why they are used in various ATMs located on the street.

Induction screens

Again, everything is clear from the name: inside the screen there is an inductor and a grid of wires. When you touch the screen with a special active pen, the tension of the created magnetic field- this is how the click is registered. The most important advantage of such a screen is the highest possible accuracy, which is why they have proven themselves well in expensive graphics tablets.

Optical screens

The principle is based on total internal reflection: the glass is illuminated by infrared illumination, and as long as there is no pressure, light rays are completely reflected at the border of glass and air (that is, there is no refracted ray). When you click on such a screen, a refracted beam appears, and from the angle of refraction (or reflection) you can calculate the point of clicking.

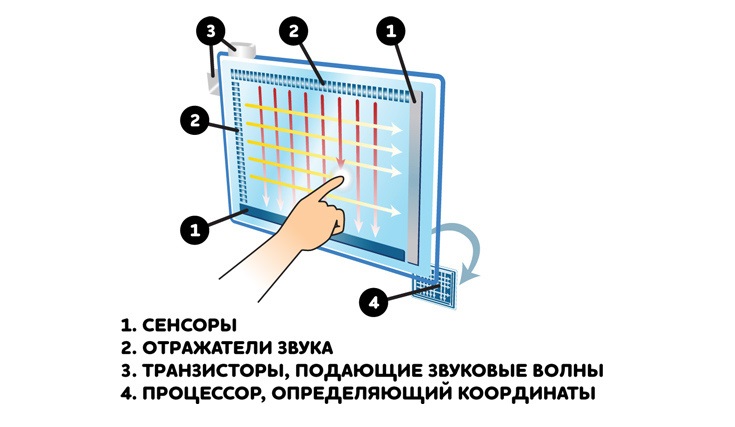

Surface acoustic wave screens

Perhaps one of the most difficult arranged screens. The principle of operation is that ultrasonic vibrations are created in the thickness of the glass. When you touch vibrating glass, the waves are absorbed, and special sensors in the corners register this and calculate the point of contact:

The advantage of this technology is that you can touch the screen with any object, not necessarily conductive or grounded. Minus - the screen is afraid of any contamination, so it will be impossible to use it, for example, in the rain.

DST screens

Their operating principle is based on the piezoelectric effect - when the dielectric is deformed, it becomes polarized, which means a potential difference arises - and it can already be calculated. The advantages are a very fast response speed and the ability to work with a seriously dirty screen. The downside is that to determine the location of the finger, it must constantly move.

That's basically all types of touch screens. Of course, most of them are outlandish and you are unlikely to come across them, but the sheer diversity and development of this technology is encouraging.