January 2017

The smartphone screen is not only an integral element of the design of a mobile device, but also one of its most important components. Long gone are the days when a color display was enough to describe a phone as cool. Today, a huge variety of screens satisfy absolutely everyone, even extremely demanding users. The other side of the coin of abundance and accessibility is that sophisticated technologies and terms are hardly accessible to the common man. Moreover, upon superficial inspection, it may seem that all screens are approximately the same and differ only in size. Upon closer examination, it becomes clear that the design of a smartphone display includes such important factors as color rendering quality, comfort of use in bright lighting, viewing angles, sensor response speed to touch, and much more.

SMARTPHONE DISPLAY COMPONENTS

The human eyes are one of the main conductors of information for the brain, so it is quite natural that the smartphone screen is the most important part of the device, because with its help, not only control is carried out, but also information is read.

The dawn of the development of electronic technologies began with the use of the cathode ray tube principle for TV and PC screens; the seventies were marked by the appearance of the first liquid crystal monochrome screen, the production technology of which, when the first mobile phones successfully migrated to this industry. Somewhat later, the use of screen production technology based on organic light-emitting diodes marked the emergence of touch and flexible displays.

Almost any smartphone display device includes the following components:

A layer of liquid crystals that transmit light rays;

The matrix responsible for forming the picture;

Light filters designed to produce a color image;

Light source.

ABOUT RESOLUTION, DIAGONAL, PIXEL DENSITY, TOUCHSCREEN TYPES AND DISPLAY TYPES

Resolution and diagonal. The parameters are extremely important for obtaining a high-quality and clear picture. It is important that the ratio of screen size and resolution is adequate, otherwise you can get a frankly grainy, low-quality image. The most common options today are: 320x480 px with a diagonal of 3.5 inches (very budget models), 480x800 px/4", 540x960 px/4.8", 720x1280 px/5-5.5" (HD picture with good detail), 1080x1920 px/from 5" and above (Full HD super image of excellent quality).

Resolution and diagonal. The parameters are extremely important for obtaining a high-quality and clear picture. It is important that the ratio of screen size and resolution is adequate, otherwise you can get a frankly grainy, low-quality image. The most common options today are: 320x480 px with a diagonal of 3.5 inches (very budget models), 480x800 px/4", 540x960 px/4.8", 720x1280 px/5-5.5" (HD picture with good detail), 1080x1920 px/from 5" and above (Full HD super image of excellent quality).

Pixel density. This indicator affects the sharpness of the screen, i.e. is an indicator of comfortable use for surfing the Internet, reading books, etc. It should be understood that large display with a low resolution the pixel density will be low. In order to avoid visible picture errors during operation, it is better to give preference to the range of 200-300 ppi.

Touchscreen type. Today, the most famous are resistive and capacitive displays.

1. Resistive type. It is a two-layer coating with transparent conductor tracks. The coordinates of the touch are determined as a result of changes in the current resistance at the point of contact. This type is almost never used now. The advantage of such screens is their low price and the ability to press point-by-point with any object, the disadvantage is their fragility, susceptibility to damage, and a gradual decrease in brightness.

2. Capacitive type. It is a single-layer coating with a conductive layer applied to the inner side; it can also be presented in the form of glass and touch film. The sensor response is carried out by determining the coordinates of the current leakage from the point of contact. The advantage of such screens is increased brightness and richness of colors, resistance to damage, the disadvantage is that they are difficult to manufacture and can only be controlled with your fingers. Resistance to damage is increased by using protective glass; contamination is prevented by applying oleophobic coating.

Screen view. In the creation of displays, the technologies most often used are liquid crystal matrices - LCD and organic light-emitting diodes - OLED. LCD is more in demand, divided into TN (features low cost and fast response with poor viewing angles and color rendition), IPS (excellent color rendition, excellent viewing angles, increased contrast and picture richness) and PLS (an upgraded version of TN). As for OLED and AMOLED, these displays do not need backlighting around the perimeter like LCDs. Their advantage is rich colors, brightness and excellent viewing angles, their disadvantage is fragility and high power consumption.

SOME DESIGN FEATURES

Of course, the design of a smartphone display is not limited to image-forming technologies. So, no less important in the formation of the screen is the presence of an air gap between the sensor and the display; this technology has a name - OGS, which means combining the sensor and matrix into a single whole. Its use has significantly improved the quality of the image and had a positive effect on reducing the thickness of the smartphone. At the same time, the technology also has an unpleasant disadvantage - if the glass is damaged, it is unlikely to be replaced separately. However, the advantages of OGS have led to the fact that other screens can only be found in very cheap models. Manufacturers of modern smartphones have not stopped there - in the last few years there has been a clear trend towards an even greater reduction in the thickness of the screen, changing the shape mainly by bending, not only of the glass and screen, but also of the mobile device as a whole.

Of course, the design of a smartphone display is not limited to image-forming technologies. So, no less important in the formation of the screen is the presence of an air gap between the sensor and the display; this technology has a name - OGS, which means combining the sensor and matrix into a single whole. Its use has significantly improved the quality of the image and had a positive effect on reducing the thickness of the smartphone. At the same time, the technology also has an unpleasant disadvantage - if the glass is damaged, it is unlikely to be replaced separately. However, the advantages of OGS have led to the fact that other screens can only be found in very cheap models. Manufacturers of modern smartphones have not stopped there - in the last few years there has been a clear trend towards an even greater reduction in the thickness of the screen, changing the shape mainly by bending, not only of the glass and screen, but also of the mobile device as a whole.

WHAT SHOULD I CHANGE IF THE GLASS OR MODULE IS DAMAGED?

To objectively assess the need to replace a damaged element, it is necessary to dwell in more detail on the following definitions:

Display. An element of a mobile device that displays graphic (image) and text data on the smartphone screen.

Touchscreen or sensor. Outer display layer that responds to touch, showing requested information.

Display module. It consists of a display and sensor glued together with special glue. Judging by consumer demand, one of the most important criteria by which a user chooses a smartphone is the size and quality characteristics of the screen, which automatically makes it the most vulnerable part of the phone, despite the fact that developers use the highest quality materials to create them.

Very often, users encounter problems such as mechanical damage to the screen - this can be falls, cracks, shocks, damage from being carried in a bag or pocket from keys and other hard and sharp objects. The first sign that the display is faulty is that the sensor stops responding to touch. And here lies the most important problem: often replacing the sensor or protective glass or it is impossible in principle, since it is a single module with the display, or it is simply not cost-effective. Therefore, in most cases, experts will suggest replacing the display module as a single unit. This factor is also a recommendation for careful handling of the smartphone, with the desirable use of accessories - films, glasses, cases.

LTPS (Low Temperature Polysilicon) technology is the latest manufacturing process for TFT LCDs. This technology uses laser annealing, which allows crystallization of the silicon film at temperatures below 400°C.

Polycrystalline silicon is a silicon-based material that contains many silicon crystals ranging in size from 0.1 to several microns. In semiconductor manufacturing, polycrystalline silicon is usually produced using LPCVD (Low Pressure Chemical Vapor Deposition) and then annealed at temperatures above 900 C. This is the so-called SPC (Solid Phase Crystallization) method . Obviously, this method cannot be used in the production of display panels, since the melting point of glass is about 650 C. Therefore, LTPS technology is a new technology intended for the production of LCD panels.

The figure below shows the structures of single-crystalline, amorphous and polycrystalline silicon.

Now let's look at several methods for forming LTPS film on a glass or plastic substrate that are currently used:

1. MIC (Metal Induced Crystallization): This is a variation of the SPC method, but compared to the conventional SPC method, it produces polycrystalline silicon at a lower temperature (approximately 500 - 600 C). This is achieved by metallizing the film before annealing. The metal allows you to reduce the energy required to activate the crystallization process.

2. Cat-CVD: With this method, a polycrystalline film is deposited, which is not subsequently subjected to heat treatment (annealing). Currently, it is already possible to carry out deposition at temperatures below 300C. However, the growth mechanism of catalytic interaction leads to cracking of the SiH4-H2 mixture.

3. Laser Annealing: This is the most popular method used nowadays. An excimer laser is used as an energy source. It heats and melts a-Si with low hydrogen content. After this, the silicon re-crystallizes in the form of a polycrystalline film.

The preparation of LTPS film is obviously more complex than a-Si film, but LTPS TFTs are 100 times more reliable than thin film transistors made using a-Si technology, and in addition, LTPS technology allows the production of CMOS integrated circuits on a glass substrate in a single cycle scheme. p-Si technology has the following main advantages compared to a-Si technology:

1. Provides the ability to manufacture driver integrated circuits on a glass substrate in a single technological cycle, which allows reducing the required number peripheral devices and cost.

2. Higher aperture ratio: Higher carrier mobility means that the required pixel charge time can be achieved using a smaller thin film transistor. This leads to the fact that a large area of the element can be used for light transmission.

3. Media for OLED: Higher carrier mobility means that the supply current is sufficient to drive OLED devices.

4. Module compactness: Due to the presence of a built-in driver, less area is required printed circuit board for the control circuit.

The characteristics of the TFT LCDs obtained in this way will be discussed below, but for now we will consider the main aspects of LTPS technology.

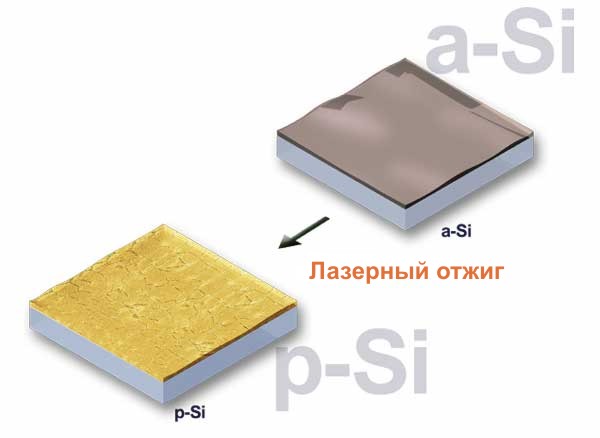

Laser annealing

During laser annealing, crystallization of the a-Si film occurs at temperatures below 400°C. The figure shows the structure of a-Si before laser annealing and the structure of p-Si obtained after laser annealing.

Electron mobility

The electron mobility in thin film transistors (TFTs) manufactured using LTPS technology reaches ~200 cm2/V*s, which is much higher than that of a-Si technology transistors (only ~0.5 cm2/V*s). Increased electron mobility makes it possible to increase the degree of integration of the integrated circuit formed on the LCD substrate, as well as to reduce the size of the thin-film transistor itself.

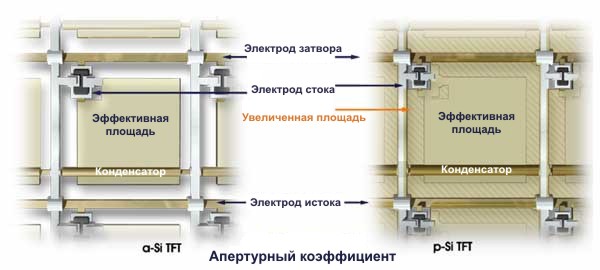

The figure below shows in a simplified way what increased electron mobility leads to.

Aperture ratio

The aperture coefficient is the ratio of the useful area of a cell to its total area. Since the thin-film transistor of an LTPS LCD is much smaller in size than an LCD transistor made using a-Si technology, the useful cell area, and, consequently, the aperture coefficient, of such an LCD will be higher. As is known, with all parameters being equal, the brightness of a cell with a large aperture coefficient will be greater!

In the figure below, you can see that the effective area of LTPS TFT is larger than that of a-Si thin film transistor.

Built-in drivers

LTPS technology allows the formation of LCDs and driver integrated circuits directly on the substrate in a single cycle. This allows you to significantly reduce the number of required external contacts and reduce the size of the substrate itself. This leads to the fact that the required reliability of the device can be achieved at lower costs, and therefore the cost of the entire product will also be lower.

The figure below shows a simplified view of an LCD manufactured using a-Si technology and an LCD with an integrated driver manufactured using LTPS technology. As you can see, the number of contacts and substrate area of the first one are much larger.

Characteristics of LTPS technology:

- Higher electron response

- Fewer connections and elements

- Low consumption

- Possibility of on-board integration of driver integrated circuits

Production of LTPS TFT LCD

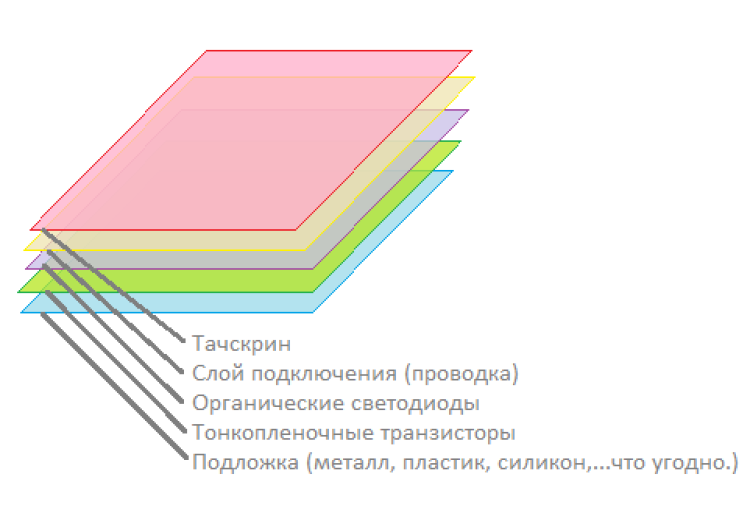

The picture below shows structural scheme produced by LTPS TFT LCD.

How to choose from the variety of modern smartphones what is right for you? Today the bad-android team has prepared material with useful tips on the topic of display selection.

How not to overpay for a device? How can you figure out what to expect from it based on the type of display?

Types of matrices

IN modern smartphones are used three basic types of matrices.

The first of them, called - is based on organic light-emitting diodes. The remaining two types are based on liquid crystals - IPS And TN+film.

It is impossible not to mention the frequently encountered abbreviation TFT.

TFT- these are thin-film transistors that control subpixels of displays (subpixels are responsible for the three primary colors, on the basis of which “full” “multicolor” pixels are formed, which we will talk about a little later).

Technology TFT applies in all three types of matrices listed above. That is why the often used comparison TFT And IPS is essentially absurd.

For many years, the main material for TFT matrices was amorphous silicon. On this moment launched an improved production of TFT matrices, in which the main material is polycrystalline silicon, significantly increasing energy efficiency. The size of the transistors has also been reduced, which allows achieving the highest performance. ppi(pixel density).

So, we’ve sorted out the matrix base, it’s time to talk directly about the data types of matrices.

At the moment, this type of matrix is the most common. Also, IPS matrices are sometimes designated by the abbreviation S.F.T..

Story IPS-matrix originates several decades ago. During this period, many different modifications and improvements were developed IPS-displays.

When listing the advantages and disadvantages of IPS, it is necessary to take into account the specific subtype. To summarize, for the list of strengths of IPS we will take the best subtype (and therefore the most expensive), and for the disadvantages we will keep in mind the cheapest subtype.

Advantages:

Excellent viewing angles (maximum 180 degrees)

High-quality color rendition

Possibility of producing high ppi displays

Good energy efficiency

Flaws:

Picture fades when the display is tilted

Possible oversaturation or, conversely, insufficient color saturation

AMOLED matrix

The matrix provides the deepest black color, compared to the other two types of matrices. But it was not always so. The first AMOLED matrices had implausible color reproduction and insufficient color depth. There was some acidity in the picture, too intense brightness.

Until now, due to internal incorrect settings, some displays are almost identical in perception to IPS. But in super-AMOLED displays, all flaws were successfully fixed.

When listing the advantages and disadvantages, let’s take a regular AMOLED matrix.

Advantages:

The highest quality picture among all existing types of matrices

Low power consumption

Flaws:

Occasionally uneven lifespan of LEDs (different colors)

The need for careful customization of the AMOLED display

Let's sum up the intermediate results. Obviously, the matrices are leaders in image quality. Exactly AMOLED displays installed on the most advanced devices. In second place are IPS matrices, but you should be careful with them: manufacturers rarely indicate the subtype of the matrix, and this is what plays a key role in the final level of the image. An unambiguous and firm “no” should be said to devices with TN+film matrices.

Subpixels

The determining factor in the final quality of the display is often hidden display characteristics. Image perception is strongly influenced by subpixels.

In case of LCD the situation is quite simple: everyone is colored ( RGB) pixel consists of three subpixels. The shape of the subpixels depends on the modification of the technology - a subpixel can be shaped like a “check mark” or a rectangle.

In the implementation of displays in terms of subpixels, everything is somewhat more complicated. In this case, the light source is the subpixels themselves. As you know, the human eye is less sensitive to blue and red colors, in contrast to green. That is why repeating the IPS subpixel pattern would significantly affect the picture quality (of course, in the worst side). To preserve the realistic color rendering, technology was invented.

The essence of the technology is to use two pairs of pixels: RG (red-green) and BG (blue-green), which, in turn, consist of corresponding subpixels of the corresponding colors. A combination of subpixel shapes is used: green ones have an elongated shape, and red and blue ones are almost square.

The technology turned out to be not very successful: the white color was frankly “dirty”, and notches appeared at the junctions of different shades. At a low rate ppi a grid of subpixels became visible. Such matrices have been installed on a number of smartphones, including flagships. The last flagship that was “lucky” to get a PenTile matrix was Samsung Galaxy S III.

Naturally, it was impossible to leave the situation with low-quality implementation of subpixels in the same state, so soon the upgrade above the described technology, which received the prefix Diamond.

By increasing ppi Diamond PenTile made it possible to get rid of the problem with jagged boundaries between colors, and white became much “cleaner” and more pleasing to the eye. And it is this development that is installed in all Samsung flagships, starting with the Galaxy S4.

And here IPS-matrices, although they are generally considered weaker than ’ov’s ones, however, have never encountered such problems.

What conclusion can be drawn? Be sure to pay attention to the quantity ppi in case of purchasing a smartphone with an -matrix. A high-quality picture is only possible with an indicator of 300 ppi. But with IPS matrices do not have such strict restrictions.

Innovative technologies

Time does not stand still; talented engineers continue to work painstakingly to improve all characteristics of smartphones, including matrices. One of the latest serious developments is technology O.G.S..

O.G.S. is an air gap between the screen itself and the projective-capacitive sensor. IN in this case the technology met expectations 100%: color rendering quality, maximum brightness and viewing angles increased.

And over the past few years O.G.S. It has become so embedded in smartphones that you won’t find the implementation of a “hamburger” display filled with an air gap except on the simplest devices.

In their search for display optimization, designers came across another interesting opportunity to improve the picture on phones. In 2011, experiments began on shape glass Perhaps the most common form of glass among the unusual ones has become 2.5D- with the help of curved edges of the glass, the edges become smoother and the screen becomes more voluminous.

Company HTC released a smartphone Sensation, the glass of which was concave in the center of the display. According to HTC engineers, this increases protection from scratches and impacts. But glass concave to the center never received widespread use.

The concept of bending the display itself, and not just the glass, as was done in . One of the side edges of the display has a curved shape.

A very interesting characteristic that you should pay attention to when buying a smartphone is sensor sensitivity. Some smartphones are equipped with a sensor with increased sensitivity, which allows you to fully use the display even with regular gloves. Also, some devices are equipped with an inductive substrate to support styluses.

So for those who like to text in the cold or use a stylus, the sensitive sensor will definitely come in handy.

Known truths

It's no secret that screen resolution also greatly affects the final level of the image. Without further comment, we present to your attention a table of correspondence between display diagonal and resolution.

Conclusion

Each matrix has its own characteristics and hidden characteristics. You should be careful with -displays, or rather, with the ppi pixel density indicator: if the value less than 300 ppi, then the picture quality will tell you frankly will disappoint.

For IPS-matrix is important subtype, and depending on the subtype, the cost of the smartphone logically increases proportionally.

Curved glass 2.5D will significantly increase the attractiveness of the picture, as will technology O.G.S..

The issue of display size is a purely individual one, but with multi-inch “shovels” a high resolution would be appropriate.

We wish you pleasant shopping, friends!

Stay tuned, more to come a lot of interesting.

When choosing a new phone, the question arises: “Which screen should I choose?” There are not many types of displays used in mobile technology. Let's look at their main characteristics.

LCD screens

The first were liquid crystal ones. Their operating principle is based on the fact that liquid crystals change their orientation under the influence of an electric field, refract and reflect light differently. There are two main types based on the type of matrix: passive and active.

The first ones are divided into:

- monochrome STN - “black and white” started with them mobile connection. For example, Nokia 1110 (2005)

- color CSTN - the next stage of STN development, the first color displays.

- UFB is a type of CSTN with increased brightness and contrast.

The main advantage of these displays is their low price and low power consumption. Monochrome screens are especially economical. This is a big plus for the budget sector. But the quality of color rendering is low, viewing angles are small, and the image that moves is very inert. and the fact that the display “blinds” in the sun has led to the fact that they are used less and less in mobile technology.

The second, that is, active matrices, have two subtypes:

OLED displays

Somewhat later, OLED displays appeared, based on fundamentally new technology. Organic LEDs have replaced liquid crystals. As picture display elements, they emit light when energized.

Similar to LCD OLED screens, there are also passive and active types.

Passive OLED screens typically have limited color reproduction. Initially used in affordable MP3 players and for screens in folding phones.

Active OLED screens, better known as AMOLED, have an operating principle that is somewhat reminiscent of TFT. Individual transistors are used to drive the pixels, and organic diodes instead of liquid crystals form the image. As you know, LEDs themselves emit light. Consequently, backlights will be redundant in OLED screens. And in LCD screens, they rely on backlighting; for this purpose, LEDs are used at the edges. Therefore, it is not surprising that the power consumption of OLED screens under normal conditions is less than that of LCD screens. It should be noted that these displays have low inertia, so watching videos is very comfortable, the picture is contrasty and very rich, and the viewing angle is almost 180 degrees.

For a long time, OLED screens suffered from a significant drawback - short service life. The first OLED screens operated for 2-3 years. Currently, the life of the display has been extended so much that the consumer will replace the phone faster than the screen will cease to exist. In OLED screens, the blue subpixels are the first to degrade, which significantly affects color reproduction. And what is very unpleasant is that the image on the display fades greatly in direct sunlight. Passive TFT displays have the same problem.

Active OLED displays, given their main disadvantage, high cost, are used in most cases in expensive models. Samsung, which was the first to introduce OLED screens for mobile phones, proposed their further development in 2010 - Super AMOLED. The first phone with an updated screen was the Samsung S8500 Wave. Note that, unlike traditional AMOLED technology, new screen It is much better compatible with the sun, lasts longer, and has richer and brighter colors. And externally, as they say, it can be seen with the naked eye, the display has become thinner.

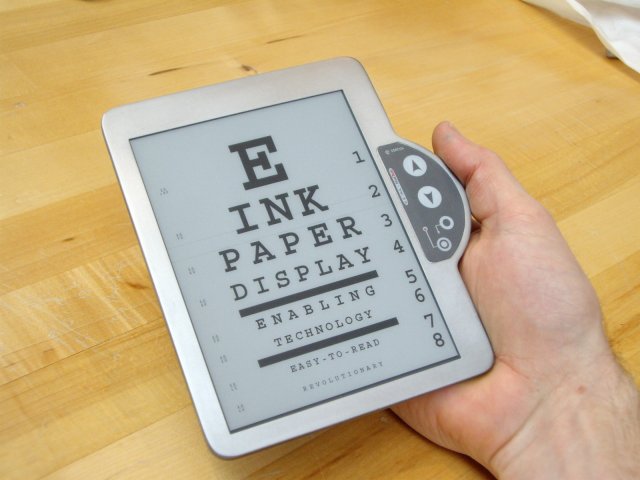

e-INK

Electronic ink displays are the most comfortable for the eyes. The technology used, in which the screen reflects light rather than emitting it, resembles the image on ordinary books or newspapers. The pixels here consist of microcapsules containing black and white particles that have negative and positive charges, respectively. Under the influence of the electric field, the particles inside the capsule move, thus forming an image. If you add a polarizing filter, you can get color e-INK screens.

The advantages of electronic ink screens include low energy consumption. This is possible due to the fact that electricity is consumed only when changing the picture and there is no need to maintain it. e-INK displays can be flexible. Still, such screens have serious disadvantages:

- Firstly, inertia, which exceeds even that of STN screens. There can be no talk of watching animation or video here at all.

- Secondly, the cost is significant.

- Thirdly, displays do not emit light. It is necessary to use separate lamps to backlight the screen in the dark, which eliminates the advantages of e-INK in terms of power consumption in low light conditions.

For displays of this type, only one market niche is considered promising - e-books for reading. But phone manufacturers continue their experiments. For example, the budget Motorola F3 uses e-INK as its main display, and the Hitachi W61H clamshell as an additional one. Here the screen is used to create pictures and patterns on the body.

How is AMOLED different from TFT?

AMOLED and TFT are two technologies vying for use in mobile phone displays. The main difference is the material: AMOLED uses organic means, mainly carbon electrodes, and TFT uses liquid crystals. AMOLED screens produce their own light, while competitors use additional backlighting.

AMOLED displays compared to TFT:

- thinner;

- show brighter and more contrasting colors;

- expensive;

- shorter service life.

It is believed that TFT displays more natural color reproduction than its competitor. The technology is capable of conveying natural white color, which in AMOLED is a little dirty or with a yellowish tint. In turn, AMOLED can reproduce natural black, which TFT has problems with. Samsung is trying its best to improve its Super AMOLED technology, creating additional programs for better picture transmission. Its new devices do not lag behind their competitors in terms of color rendering.

In the year 2007, when buying another mobile phone, we evaluated its design, rarely paying attention to functionality and what’s more, the screen is color, not too small, and that’s great. Today, mobile devices can hardly be distinguished from each other, but the most important characteristic for many, what remains is the screen and not only its diagonal size, but also matrix type. Let's see what's behind the terms TFT, TN, IPS, PLS, and how to choose a smartphone screen with the required characteristics.

Types of matrices

Currently, modern mobile devices use three technologies for producing matrices based on:

- liquid crystal display (LCD): TN+film And IPS;

- on organic light-emitting diodes (OLED) – AMOLED.

Let's start with TFT(thin-film transistor), which is a thin-film transistor used to control the operation of each subpixel. This technology used in all of the above types of screens, including AMOLED, so comparing TFT and IPS is not always correct. The vast majority of TFT matrices use amorphous silicon, but TFTs on polycrystalline silicon (LTPS-TFTs) have also begun to appear, the advantage of which is reduced power consumption and higher pixel density (more than 500 ppi).

TN+film (TN)– the simplest and cheapest matrix used in mobile devices with small viewing angles, low contrast and low color accuracy. This type of matrix is installed in the cheapest smartphones.

IPS (or SFT)- the most common type of matrix in modern mobile gadgets, which have wide viewing angles (up to 180 degrees), realistic color reproduction and provide the ability to create displays with high pixel density. This type of matrices has several types, let’s consider the most popular ones:

- AH-IPS– from LG;

- PLS- from Samsung.

It makes no sense to talk about advantages relative to each other, since the matrices are identical in properties and characteristics. You can distinguish a cheap IPS matrix by eye by its characteristic properties:

- fading of the picture when the screen is tilted;

- low color accuracy: an image with oversaturated or very dull colors.

Standing apart from LCD are matrices created on the basis of organic light-emitting diodes (OLED). Mobile devices use a type of OLED technology - matrix AMOLED, demonstrating the deepest blacks, low power consumption and overly saturated colors. By the way, the life of AMOLED is limited, but modern organic LEDs are designed for at least three years of continuous operation.

Conclusion

The highest quality and brightest images are currently provided by AMOLED matrices, but if you are looking at a non-Samsung smartphone, I recommend an IPS screen. Mobile devices with a TN+film matrix are simply technologically outdated. I recommend not buying a smartphone with AMOLED screen, which has a pixel density of less than 300 ppi, this is due to the problem of subpixel patterns in this type matrices

Perspective matrix type

– the most promising displays based on quantum dot technology. A quantum dot is a microscopic piece of semiconductor in which quantum effects play an important role. QLED matrices in the future will have better color rendition, contrast, higher brightness and lower power consumption.